- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

TR-1060L Open type heat shrink baking machine

- group name

- Heat Shrink Baking Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-1060L

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Sat, 28 Feb 2026 01:10:24 GMT

Paramtents

Power AC220V/50HZ,

Application Semi-automatic Heat Shrink Tube Baking Machine

Feature Stable Performance

Warranty 1year

Contact Coco 0086-18666170785

Packging & Delivery

-

Min Order1 piece

Briefing

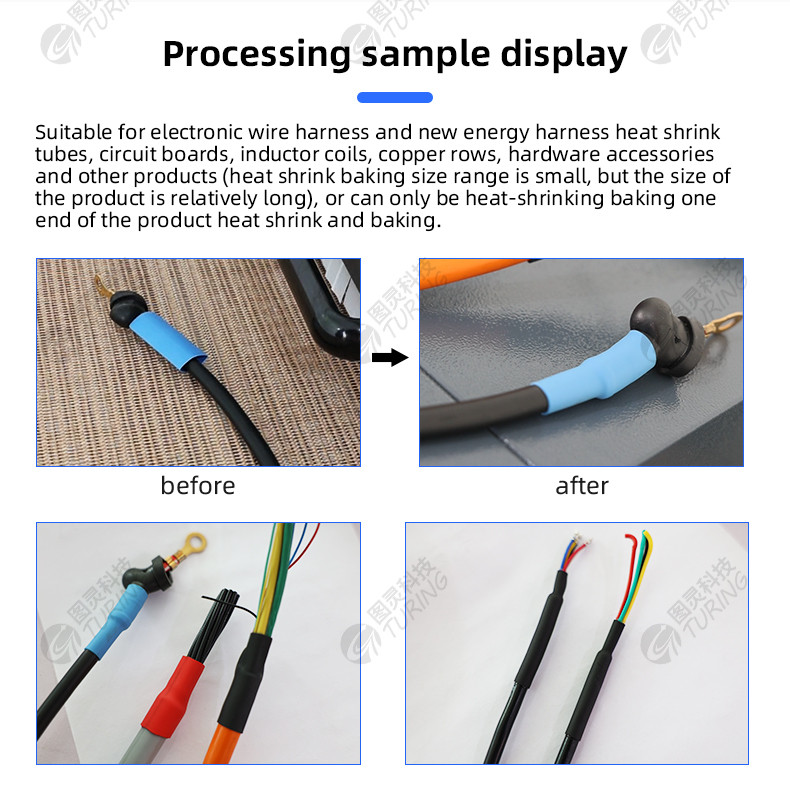

TR-1060L Open type heat shrink baking machine,uses far-infrared heat pipe heat, up and down the left and right are installed heat pipe, can be heated at the same time,and is equipped with high-speed centrifugal fan, heating fan can be stirred evenly heat, so that the entire box to maintain a constant temperature.

Detailed

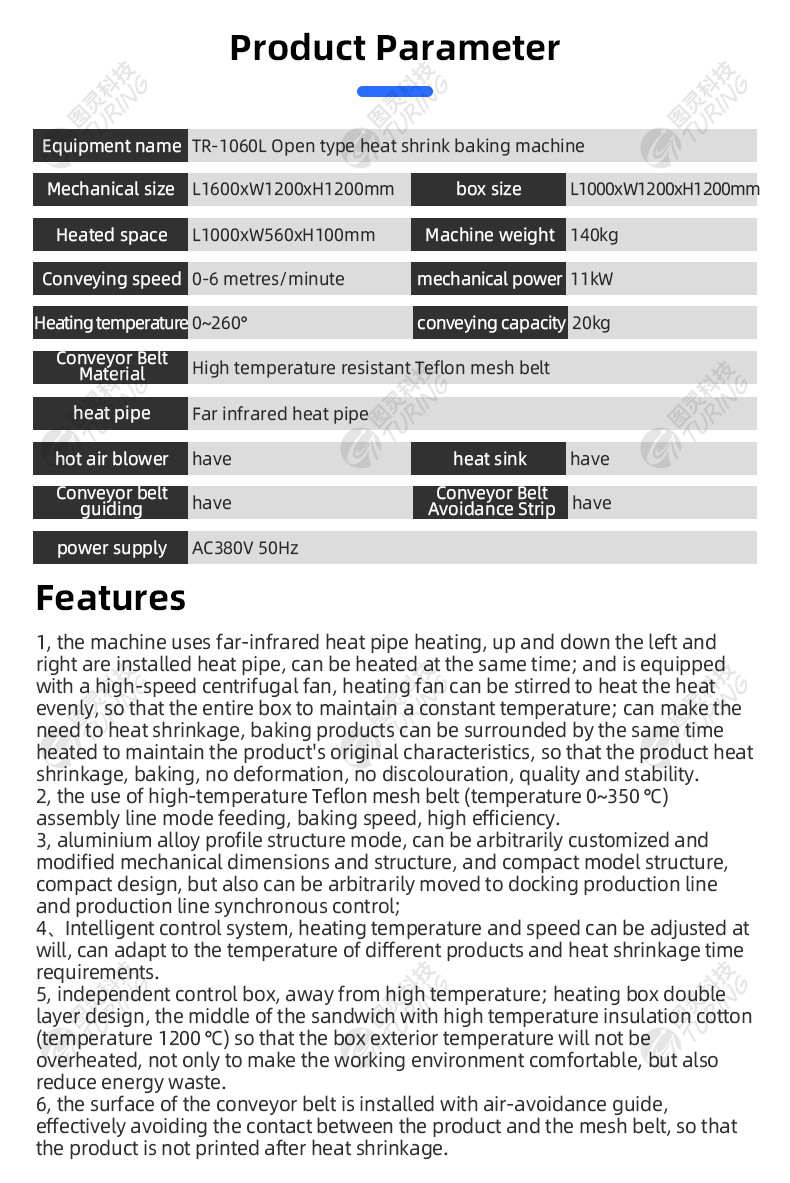

1, the machine uses far-infrared heat pipe heating, up and down the left and right are installed heat pipe, can be heated at the same time; and is equipped with a high-speed centrifugal fan, heating fan can be stirred to heat the heat evenly, so that the entire box to maintain a constant temperature; can make the need to heat shrinkage, baking products can be surrounded by the same time heated to maintain the product's original characteristics, so that the product heat shrinkage, baking, no deformation, no discolouration, quality and stability.

2, the use of high-temperature Teflon mesh belt (temperature 0~350 ℃) assembly line mode feeding, baking speed, high efficiency.

3, aluminium alloy profile structure mode, can be arbitrarily customized and modified mechanical dimensions and structure, and compact model structure, compact design, but also can be arbitrarily moved to docking production line and production line synchronous control;

4、Intelligent control system, heating temperature and speed can be adjusted at will, can adapt to the temperature of different products and heat shrinkage time requirements.

5, independent control box, away from high temperature; heating box double layer design, the middle of the sandwich with high temperature insulation cotton (temperature 1200 ℃) so that the box exterior temperature will not be overheated, not only to make the working environment comfortable, but also reduce energy waste.

6, the surface of the conveyor belt is installed with air-avoidance guide, effectively avoiding the contact between the product and the mesh belt, so that the product is not printed after heat shrinkage.