- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

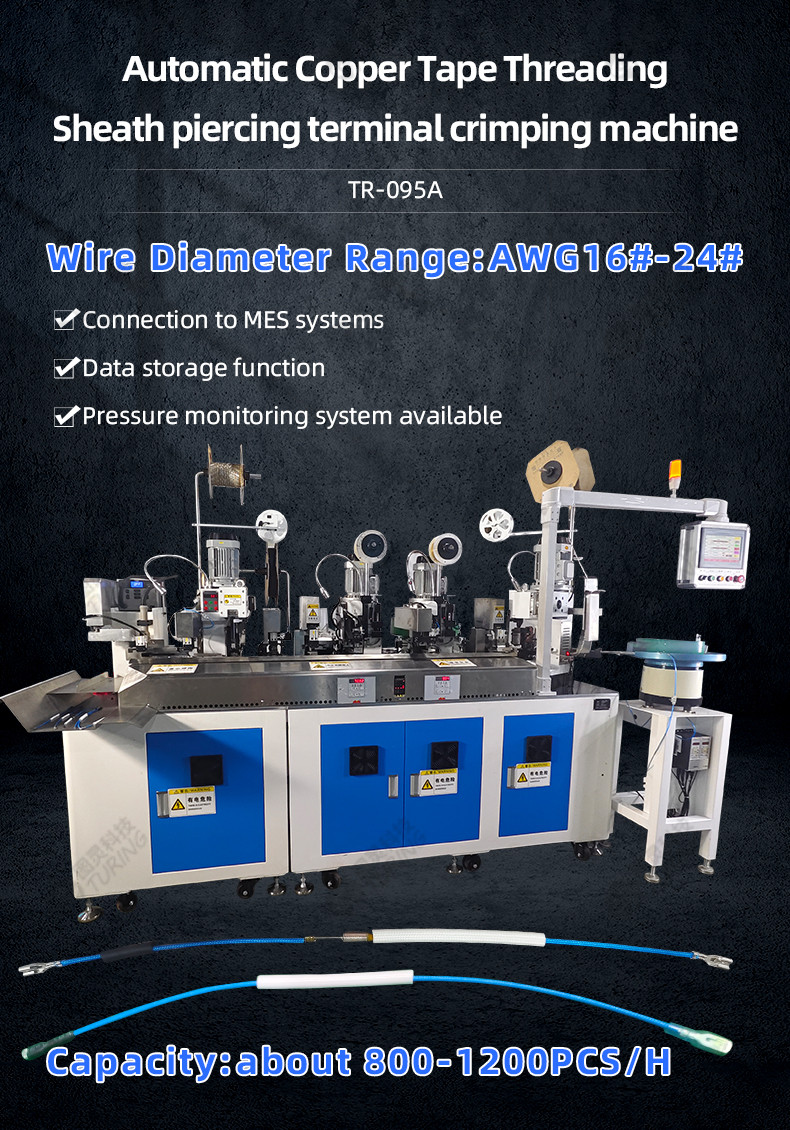

TR-095A Fully automatic copper strip threading tube and sheath terminal crimping machine Resistance riveting machine

- group name

- Fully Automatic Copper Tape Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-095A

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Thu, 26 Feb 2026 14:58:45 GMT

Paramtents

Power AC220V/50HZ,

Feature Stable Performance

Warranty 1year

Contact Coco 0086-18666170785

Packging & Delivery

-

Min Order1 piece

Briefing

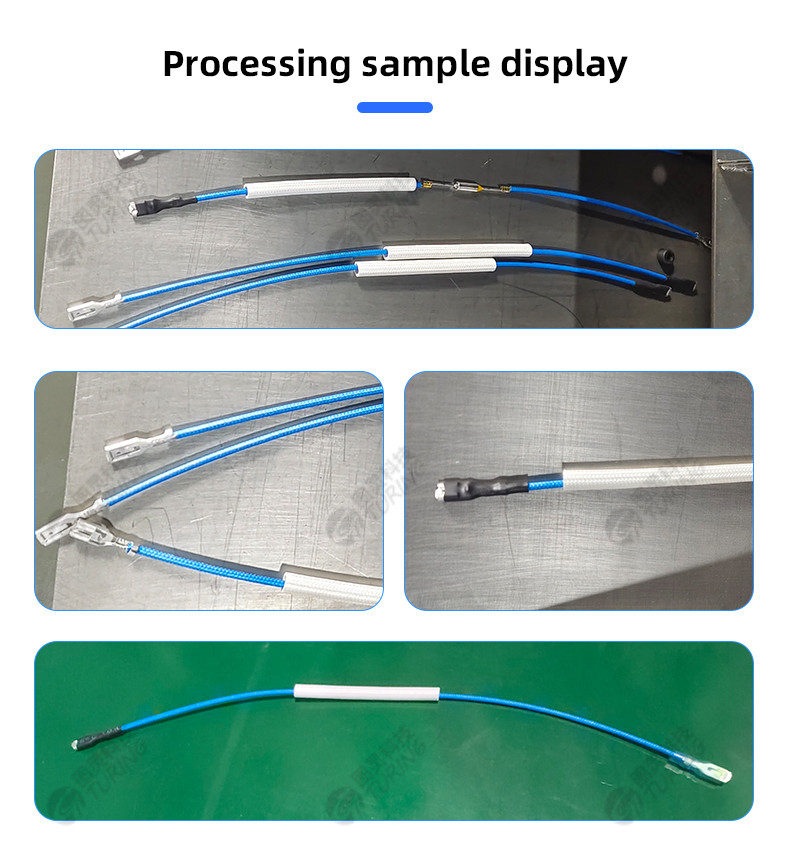

TR-095A Fully automatic copper strip threading tube and sheath terminal crimping machine Resistance riveting machine

Detailed

TR-095A Fully automatic copper strip threading tube and sheath terminal crimping machine Resistance riveting machine

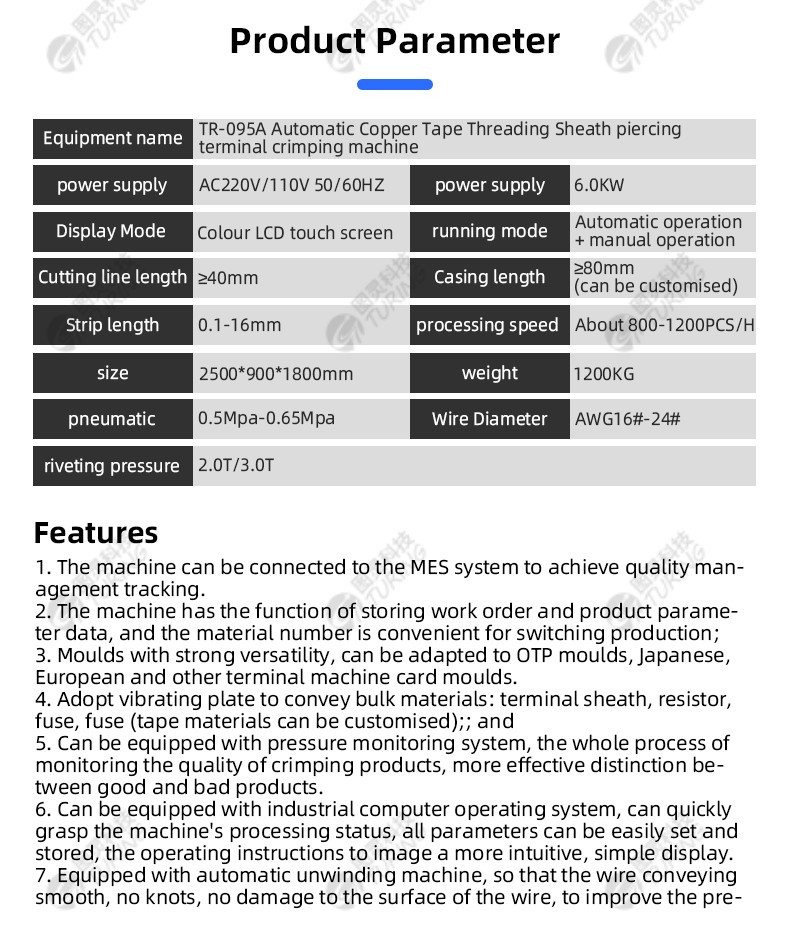

power supply:AC220V/110V 50/60HZ

power supply:6.0KW

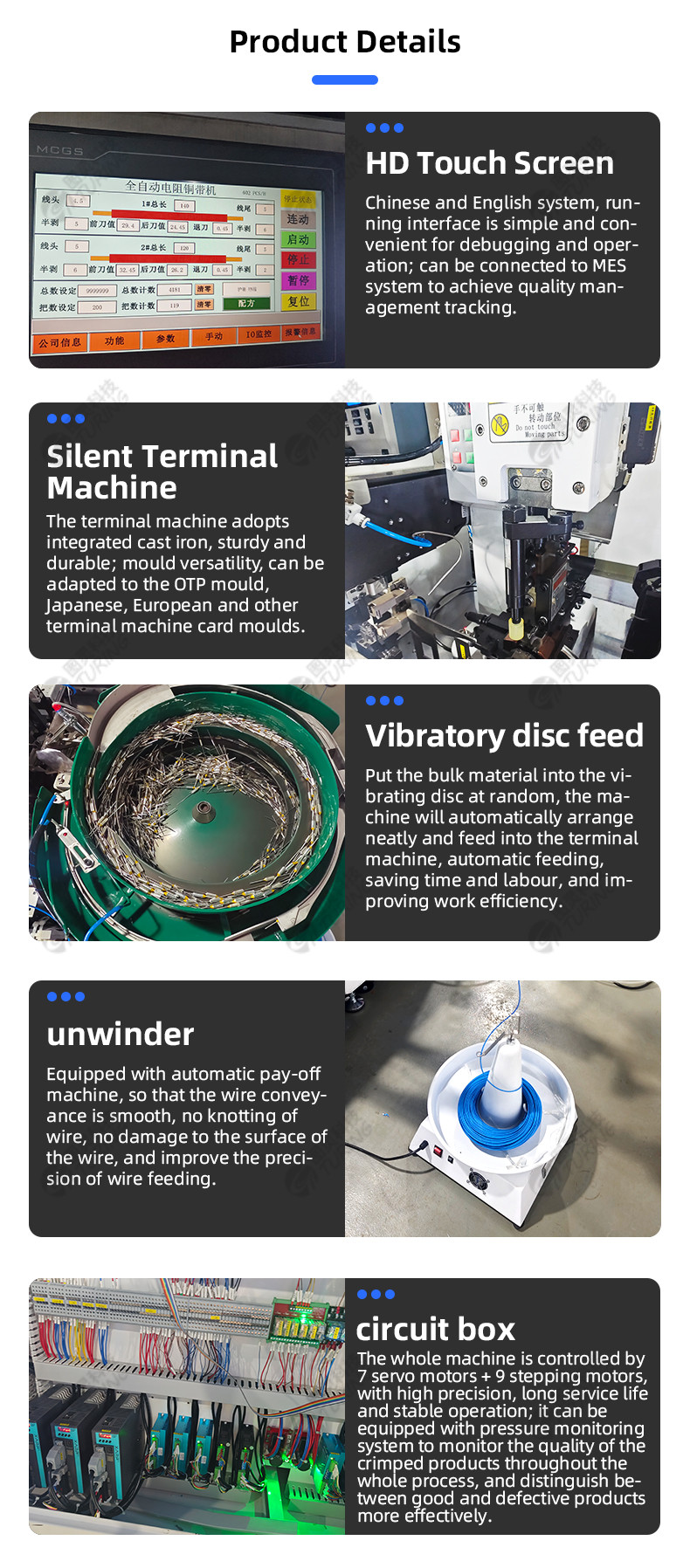

Display Mode :Colour LCD touch screen

running mode:Automatic operation + manual operation

Cutting line length:≥40mm

Casing length:≥80mm (can be customised)

Strip length:0.1-16mm

processing speed :About 800-1200PCS/H

size:2500*900*1800mm

weight:1200KG

pneumatic:0.5Mpa-0.65Mpa

Wire Diameter:AWG16#-24#machine

riveting pressure:2.0T/3.0T

Features

1. The machine can be connected to the MES system to achieve quality management tracking.

2. The machine has the function of storing work order and product parameter data, and the material number is convenient for switching production;

3. Moulds with strong versatility, can be adapted to OTP moulds, Japanese, European and other terminal machine card moulds.

4. Adopt vibrating plate to convey bulk materials: terminal sheath, resistor, fuse, fuse (tape materials can be customised)

5. Can be equipped with pressure monitoring system, the whole process of monitoring the quality of crimping products, more effective distinction between good and bad products.

6. Can be equipped with industrial computer operating system, can quickly grasp the machine's processing status, all parameters can be easily set and stored, the operating instructions to image a more intuitive, simple display.

7. Equipped with automatic unwinding machine, so that the wire conveying smooth, no knots, no damage to the surface of the wire, to improve the precision of the wire feeding

8. Full automation to complete the production, improve work efficiency and product quality, and also save labour costs.