- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

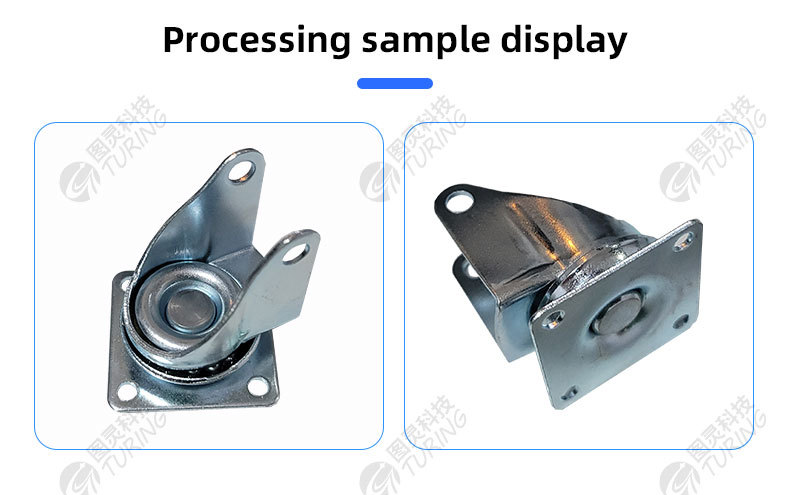

TR-JL04 double manual caster machine (hydraulic type)

- group name

- Caster Assembly Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-JL04

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Thu, 12 Feb 2026 19:22:07 GMT

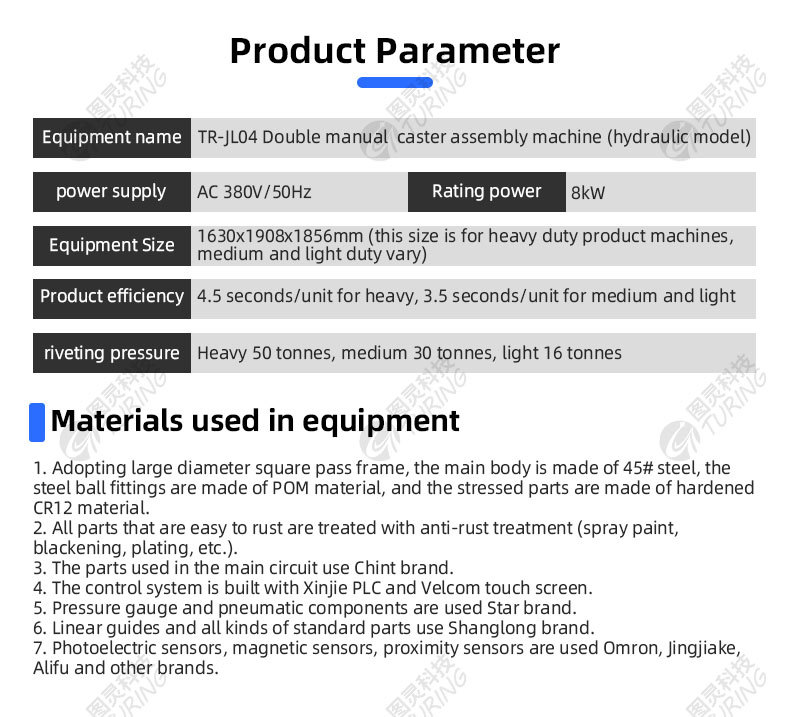

Paramtents

Speed 15-20pcs/min

Contact Coco 0086-18666170785

PLC Brand Xinjie

Packging & Delivery

-

Min Order1 piece

Briefing

TR-JL04 double manual caster machine (hydraulic type)

15-20 pcs/min , Coco 0086-18666170785

15-20 pcs/min , Coco 0086-18666170785

Detailed

TR-JL04 double manual caster machine (hydraulic type)

Materials used in equipment

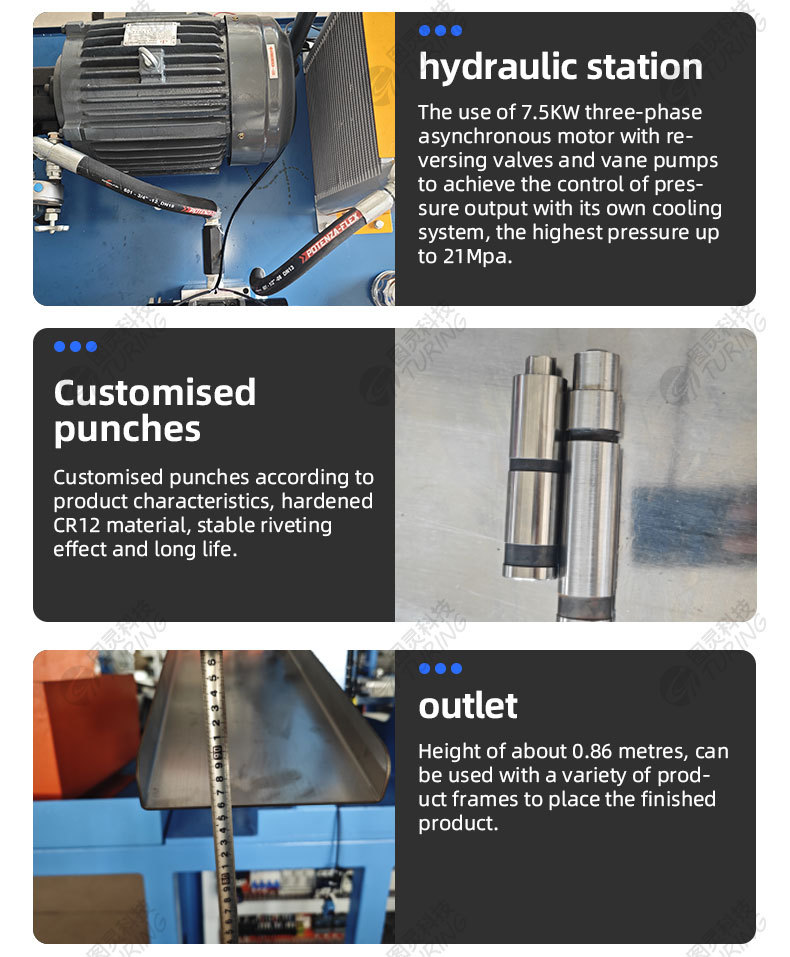

1. Adopting large diameter square pass frame, the main body is made of 45# steel, thesteel ball fittings are made of POM material, and the stressed parts are made of hardened

CR12 material.

2. All parts that are easy to rust are treated with anti-rust treatment (spray paintblackening, plating, etc.).

3. The parts used in the main circuit use Chint brand.

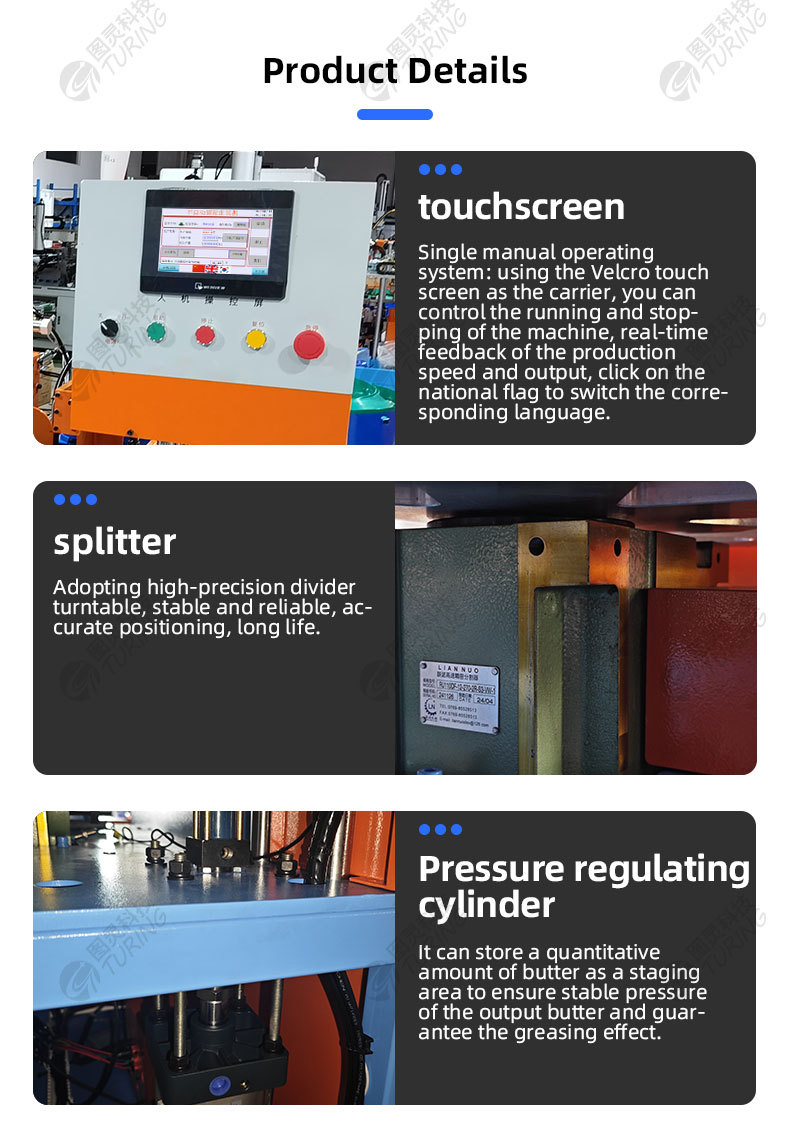

4. The control system is built with Xinjie PLc and Velcom touch screen.

5. Pressure gauge and pneumatic components are used Star brand.

6. Linear quides and all kinds of standard parts use Shanglong brand.

7. Photoelectric sensors, magnetic sensors, proximity sensors are used Omron, jingjiakeAlifu and other brands.

Equipment Description

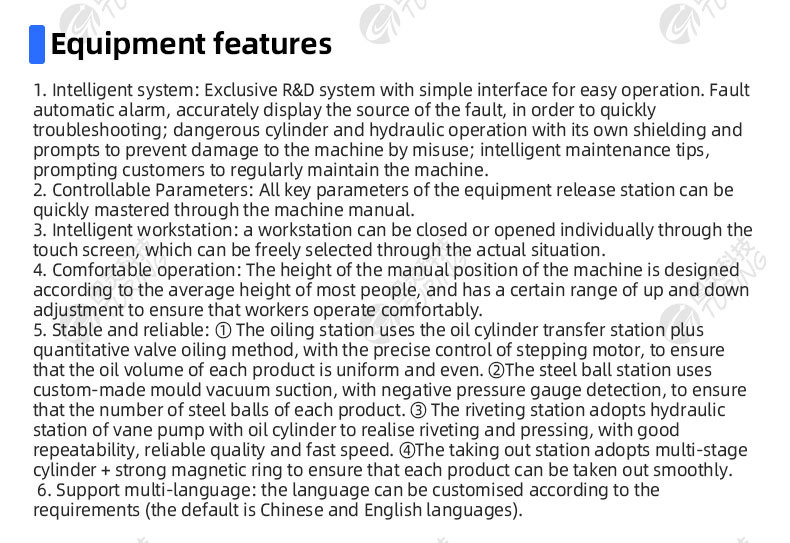

1. Intelligent system: Exclusive R&D system with simple interface for easyoperation. Fault automatic alarm, accurately display the source of the fault, inorder to quickly troubleshooting; dangerous cylinder and hydraulic operationwith its own shielding and prompts to prevent damage to the machine by misuse;intelligent maintenance prompts, prompting customers to maintain the machineon a regular basis.

2. Controllable Parameters: All key parameters of the equipment release stationcan be quickly mastered through the machine manual.

3. Intelligent workstation: a workstation can be individually closed or openedthrough the touch screen, which can be freely selected through the actualsituation.

4. Comfortable operation: The height of the manual position of the machine isdesigned according to the average height of most people, and has a certainrange of up and down adjustment to ensure that workers operate comfortably.Stable and reliable:

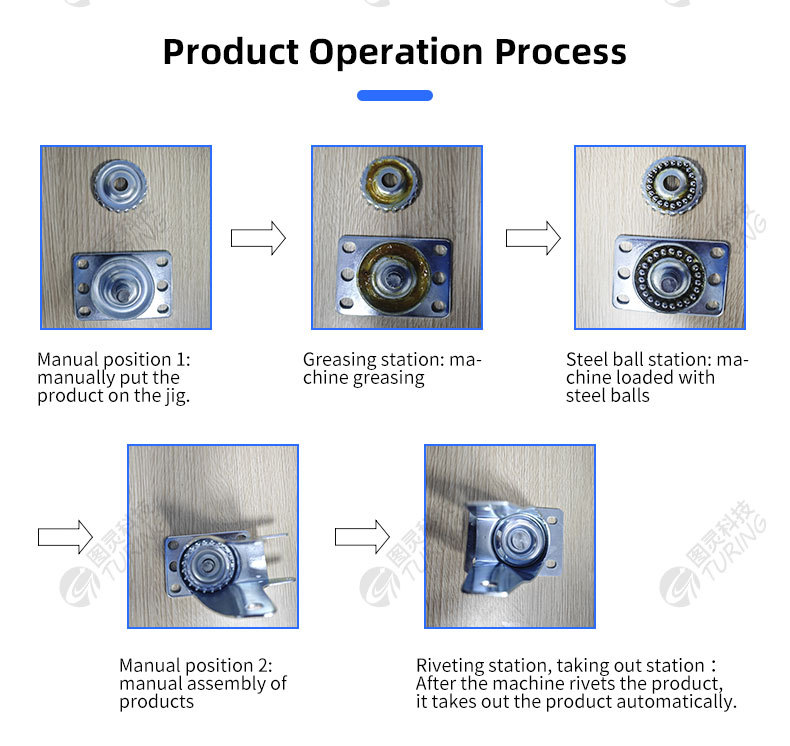

①Manual position (put the bracket to the turntable jig; transfer the bracket withthe steel ball to the big bobbin plate; put on the small plucking plate).

②) Load mandrel/bottom plate, manually stack the bottom plate into the materialchute, the cylinder mechanism automatically discharges the material to theconveyor line, the mandrel is automatically threaded and then clamped by thecylinder guide mechanism and put into the turntable fixture, the mandrel isautomatically loaded by the vibrating disc. The mandrel threading mechanismwith guiding function ensures the fast and stable threading of nails every time.

③Install the big pulling disc, the big pulling disc is automatically loaded by thevibrating disc, and put into the turntable fixture by the cylinder guide mechanism+strong magnet suction method.

③The oiling station uses the oil cylinder transfer station and quantitative valve todispense oil, which is accurately controlled by stepping motor to ensure the oilquantity of each product is uniform and even.

⑤ Big pulling plate/stands loading steel ball, loading steel ball station usingcustom mould vacuum suction, with negative pressure gauge detection, toensure that the number of steel balls of each product.

(6) Riveting, the riveting station adopts the hydraulic station of vane pump withoil cylinder to achieve riveting, with good repeatability, reliable quality and fastspeed.

(7)Finished products take out, using multi-stage cylinder + strong magnetic ringto ensure that each product can be taken out smoothly.

(8) bottom plate rotation detection (Note: this station is non-standard optionalstation), the use of servo motors + pneumatic clamp mode, can detect the bottomplate and bracket riveting whether the flexible rotation, OK products and NGproducts can be automatically differentiated into separate open material frame.5. Support multi-language: customised language according to demand (defaultChinese and English two languages),