- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Faqs

- News

- Certificate

- Contact us

TR-10TS 10T CNC servo terminal crimping machine servo pressure machinery

- group name

- New Energy Servo Terminal Crimping Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-10TS

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Sat, 27 Dec 2025 04:05:01 GMT

Paramtents

Power AC220V/50HZ,

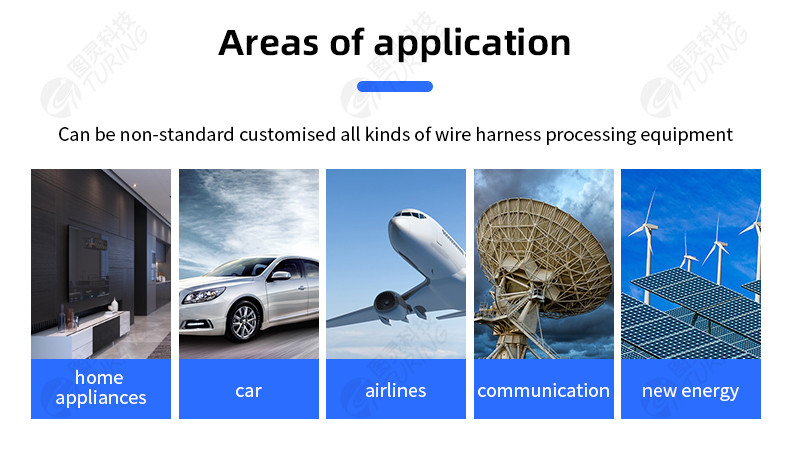

Application Intelligent Servo Terminal Crimping Machine

Feature Stable Performance

Warranty 1year

Contact Coc 0086-18666170785

Packging & Delivery

-

Min Order1 piece

Briefing

TR-20TS 20T CNC servo terminal crimping machine

Coc 0086-18666170785

Coc 0086-18666170785

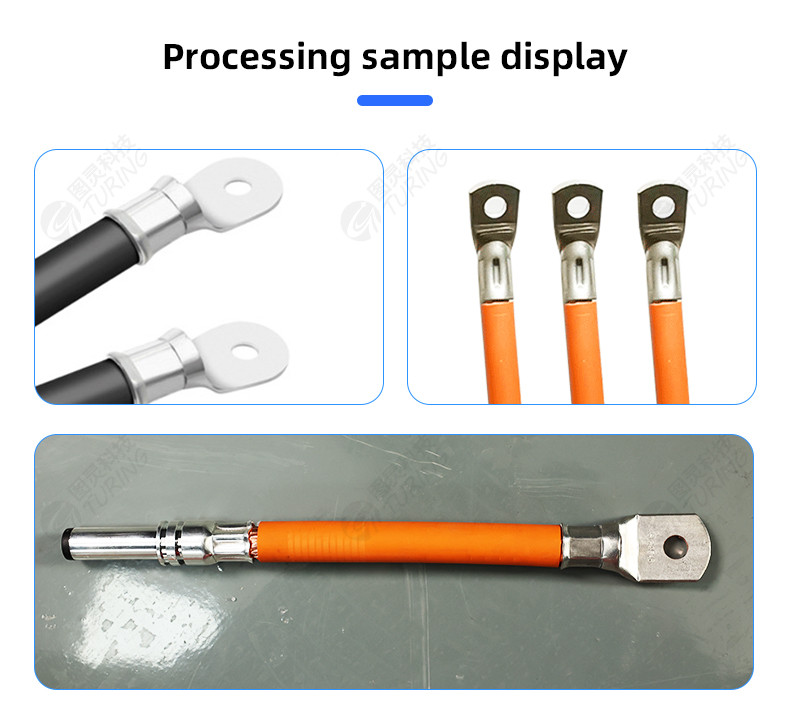

Detailed

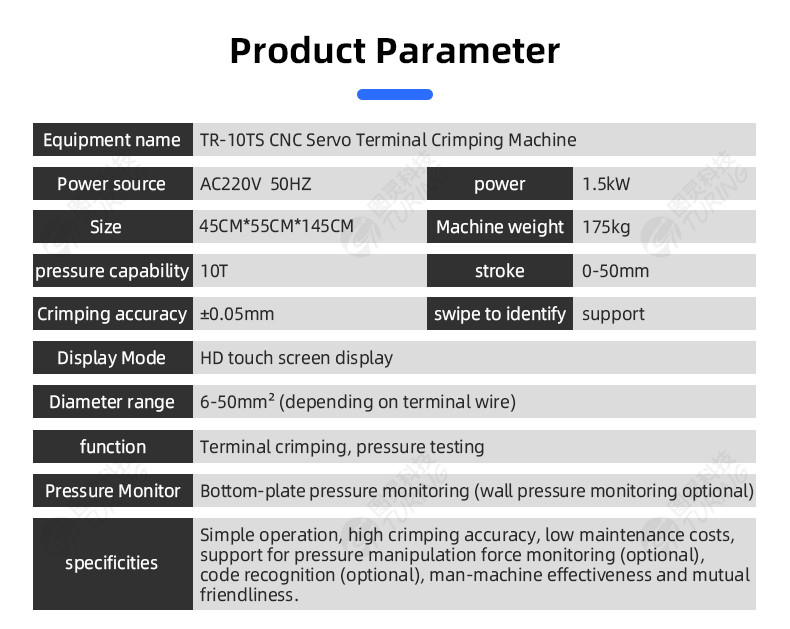

TR-10TS 10T CNC servo terminal crimping machine servo pressure machinery

Power source : AC220V 50Hz 1.5kW

Size & weight : 45cm*55cm*145cm,175kg

Pressure capability : 10T

Stroke : 0-50mm

Crimping accuracy : ±0.05mm

Swipe to identify : support

Display Mode : HD touch screen display

Diameter range : 6-50mm² (depending on terminal wire)

Function : Terminal crimping, pressure testing

Pressure Monitor : Bottom-plate pressure monitoring (wall pressure monitoring optional)

Specificities : Simple operation, high crimping accuracy, low maintenance costs,

support for pressure manipulation force monitoring (optional),

code recognition (optional), man-machine effectiveness and mutual

friendliness.

Functional features

-HMI interface operation, friendly interaction;

-Pressure monitoring (optional), automatic shutdown for bad crimping;

-Mould quick change (optional), standard base, convenient and quick;

-5µm electronic ruler accurate crimping, to ensure crimping accuracy;

-High crimping precision, new generation servo motor, high precision, low noise;

-Simple maintenance, optimised design, modular function, make the maintenance more simple and clear;

Products

The equipment is a new type of automatic CNC servo crimping equipment, beautifulappearance, the use of advanced servo motors, motion control cards and touch screencontrol system composed of intuitive understanding and set the working parameters ofthe full digital processing, optional pressure sensors, real-time observation of the statusof the terminals, to a greater extent to ensure that the yield of the product. At the sametime with authority hierarchy management, optional code recognition and otherfunctions to greatly improve the efficiency of the factory.

Functional features

HMl interface operation, friendlyinteraction;Pressure monitoring (optional),automatic shutdown for bad crimping;Mould quick change (optional), standard base, convenient and quick;5um electronic ruler accurate crimping, to ensure crimping accuracy;High crimping precision, new generation servo motor, high precision, low noise;Simple maintenance, optimised design, modular function, make the maintenance moresimple and clear;

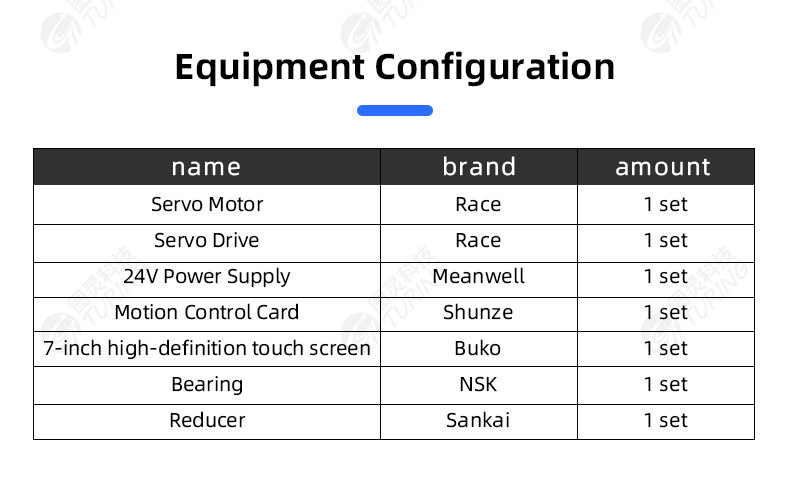

SERVO MOTOR DRIVE

Overcome the traditional motor out-of-step problems,to achieve high-precision operation, with a fast response Simple manipulation,low noise, low energy consumption and so on.

INDUSTRIAL COMPUTEROPERATION

Touch screen operation, control system integration,data traceability Industry 4.0, can be docked with thefactory MODBUS system three levels of authority settings,more reliable parameter settings, can store 120 kinds ofprocessing parameters program, convenient debugging