- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

TR-K9GZ Two axis servo copper tape machine

- group name

- Semi-auto Copper Strip Crimping Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-K9GZ

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Tue, 17 Feb 2026 22:12:38 GMT

Paramtents

Power AC220V/50HZ,

Name Copper Tape Crimping Machine

Feature Stable Performance

Warranty 1year

Contact Lily 0086-13715588365

Packging & Delivery

-

Min Order1 piece

Briefing

TR-K9GZ Two axis servo copper tape machine

Lily +8613715588365

Lily +8613715588365

Detailed

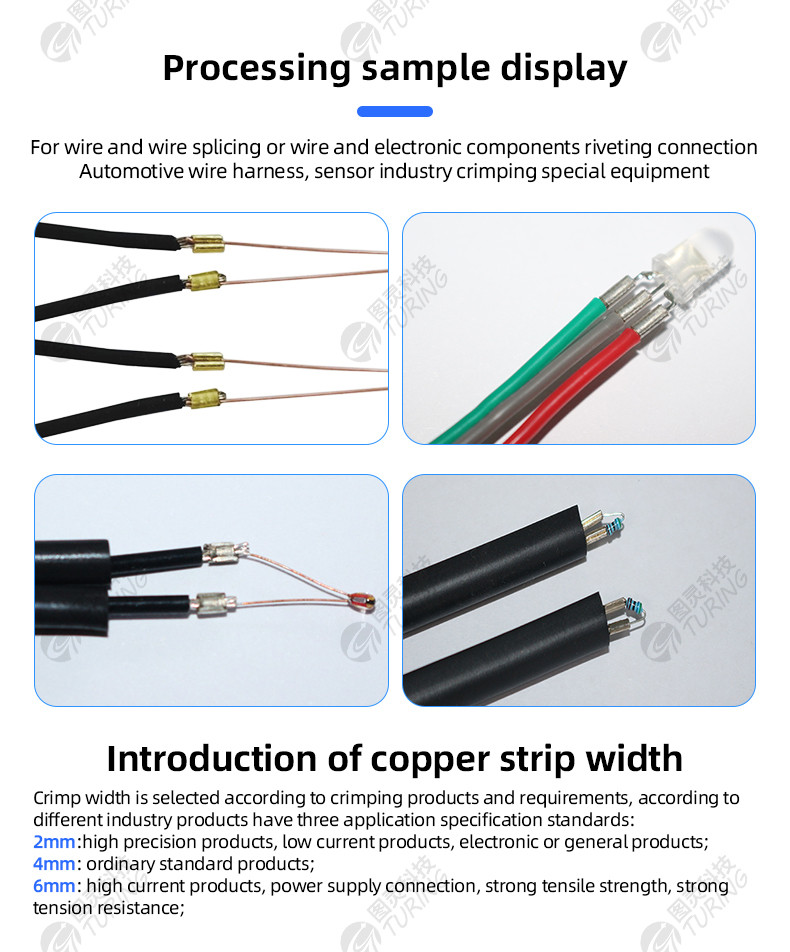

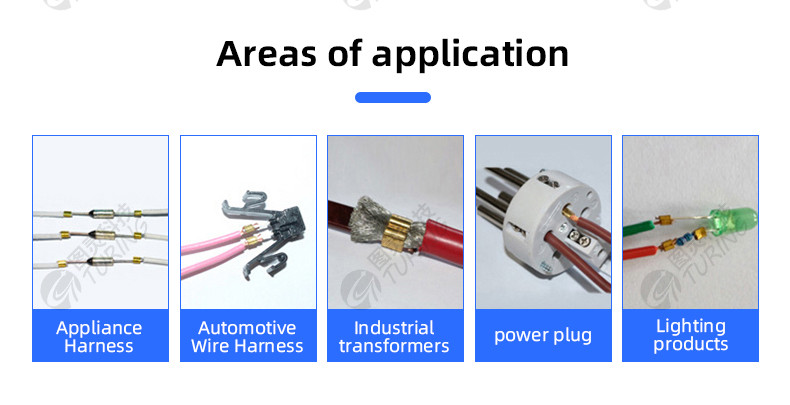

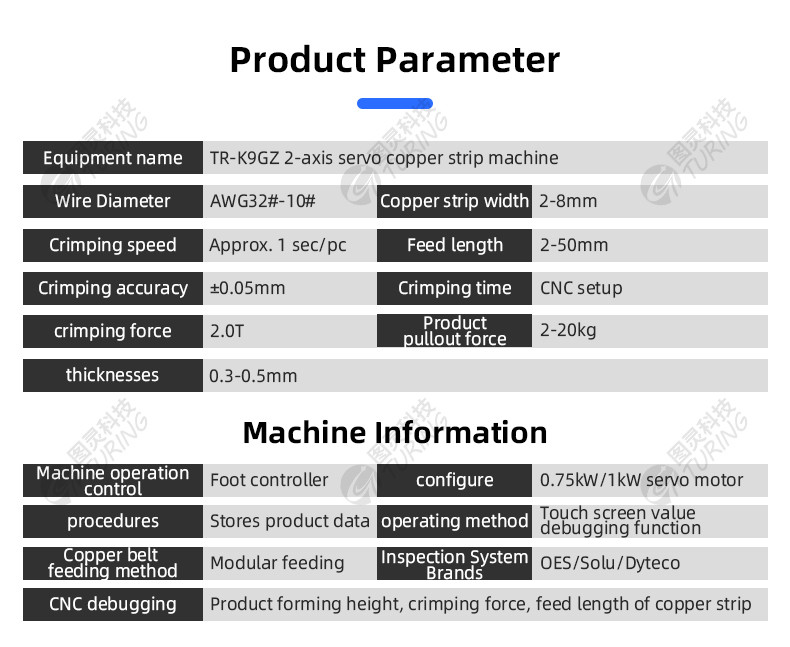

TR-K9GZ Two axis servo copper tape machine

Wire Diameter:AWG32#-10#

Copper strip width:2-8mm

Crimping speed:Approx. 1 sec/pc

Feed length:2-50mm

Crimping accuracy:±0.05mm

Crimping time:CNC setup

crimping force:2.0T

Product

pullout force:2-20kg

thicknesses:0.3-0.5mm

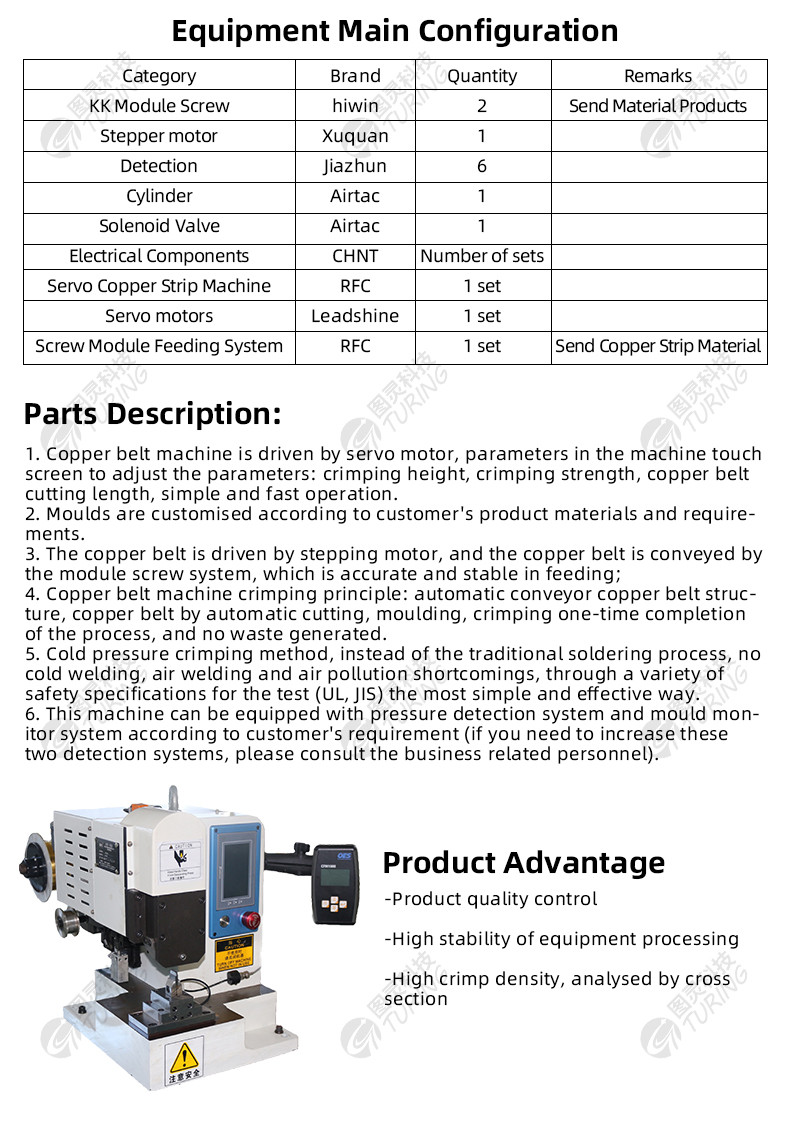

Parts Description:

1. Copper belt machine is driven by servo motor, parameters in the machine touchscreen to adjust the parameters: crimping height, crimping strength, copper beltcutting length,simple and fast operation.

2. Moulds are customised according to customer's product materials and require-ments.

3. The copper belt is driven by stepping motor, and the copper belt is conveyed bythe module screw system, which is accurate and stable in feeding;

4. Copper belt machine crimping principle: automatic conveyor copper belt struc.ture, copper belt by automatic cutting, moulding, crimping one-time completionof the process,and no waste generated.

5. Cold pressure crimping method, instead of the traditional soldering process, nocold welding, air welding and air pollution shortcomings, through a variety ofsafety specifications for the test (UL, JlS) the most simple and effective way.

6. This machine can be equipped with pressure detection system and mould mon-itor system according to customer's requirement (if you need to increase thesetwo detection systems, please consult the business related personnel).

Automatic Crimping Machine, Fully Automatic Wire Stripping and Crimping Machine, Wire Cutting Stripping and Crimping Machine, Wire Sealing and Crimping Machine, Cable Cutting Stripping and Crimping Machine, semi automatic crimping machine, rj45 automatic crimping machine, fully automatic crimping machine, jst automatic crimping machine, molex automatic crimping machine, ap-k2n semi-automatic crimping machine, artos automatic crimping machine, komax automatic crimping machine, small automatic crimping machine, automatic crimping machine price, how to use an automatic machine, automatic wire cutting stripping and crimping machine, automatic stripping and crimping machine, automatic ferrule and wire crimping machine, automatic wire stripping and crimping machine, cf3000 automatic ferrule and wire crimping machine, automatic cutting and crimping machine, automatic loading and crimping machine, automatic wire crimping machine, b crimper, automatic wire crimper machine,auto cutting winding binding machines, auto-cutting coiling binding machines, auto-cutting winding tying machines, wire coiling machines, tubing coiler machines, coiler machines, hose coiler machines, automatic coil winding machines, automatic rope coiler, tube coiling machines, auto cutting winding binding machine, automatic perfect binding machine, auto bobbin winder