- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

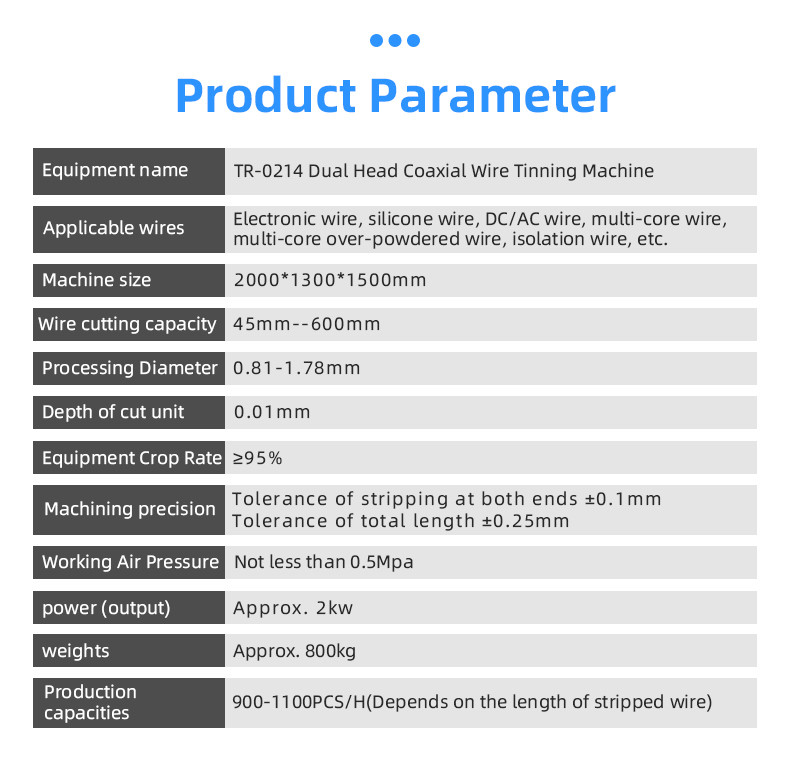

TR-0214 Double-head coaxial line tin dipping machine

- group name

- Dipping Tin Terminal Crimping Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-0214

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Tue, 03 Feb 2026 07:20:46 GMT

Paramtents

Power AC220V/50HZ, 300W

Application TR-0214 Double-head coaxial line tin dipping machi

Feature Stable Performance

Warranty 1year

Control Servo and Step motor

Contact Lily 0086-13715588365

Packging & Delivery

- 180cm x120cm x150cm

-

Min Order1 piece

Briefing

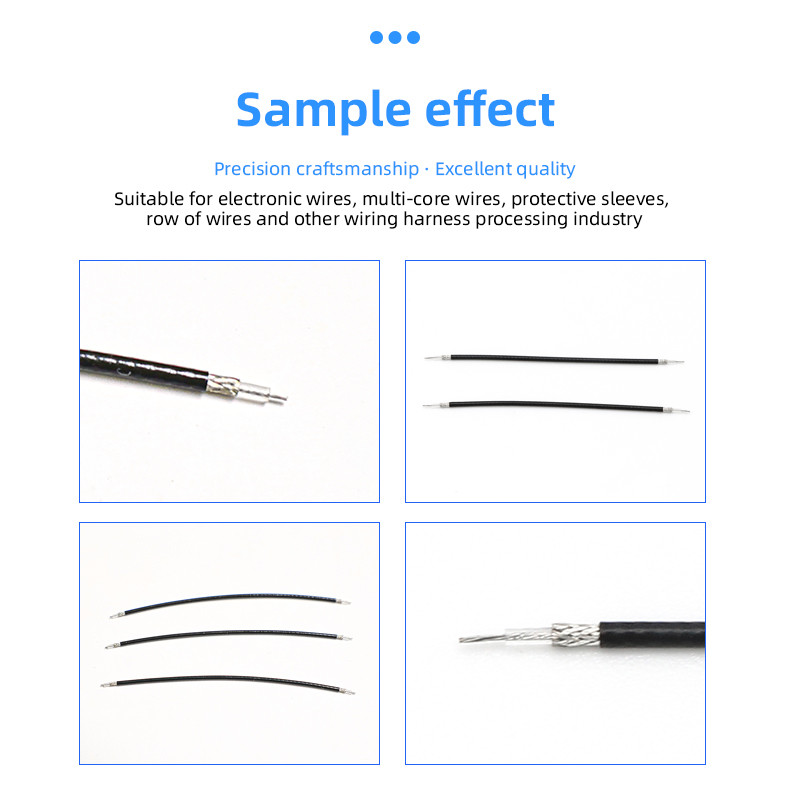

TR-0214 Double-head coaxial line tin dipping machine

Lily +8613715588365

Lily +8613715588365

Detailed

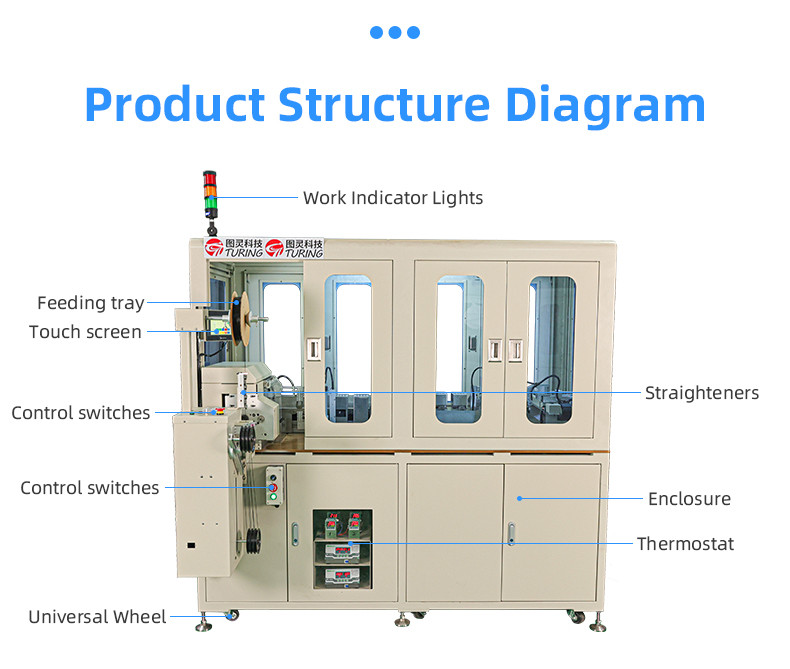

TR-0214 Double-head coaxial line tin dipping machine

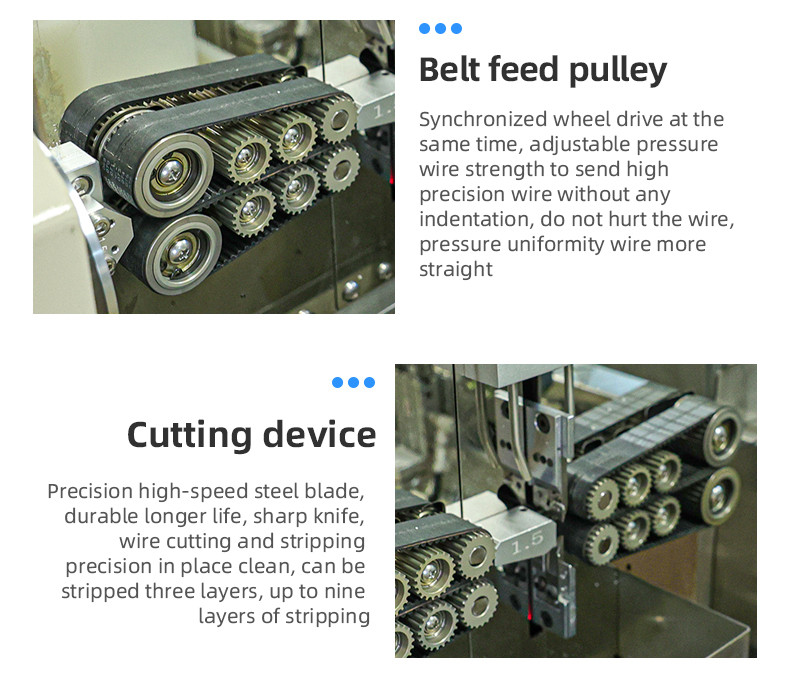

Cutting device

Precision high-speed steel bladedurable longer life, sharp knife,wire cutting and strippingprecision in place clean,can bestripped three layers,up to ninelayers of stripping

Belt feed pulley

Synchronized wheel drive at thesame time, adjustable pressurewire strength to send highprecision wire without anyindentation, do not hurt the wirepressure uniformity wire morestraight

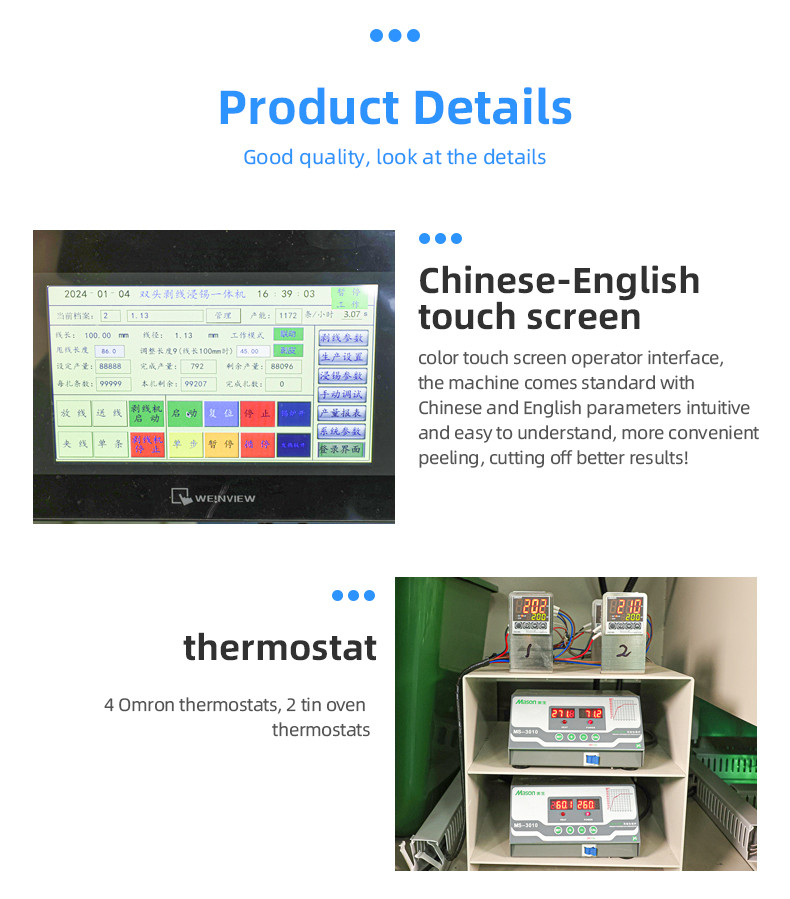

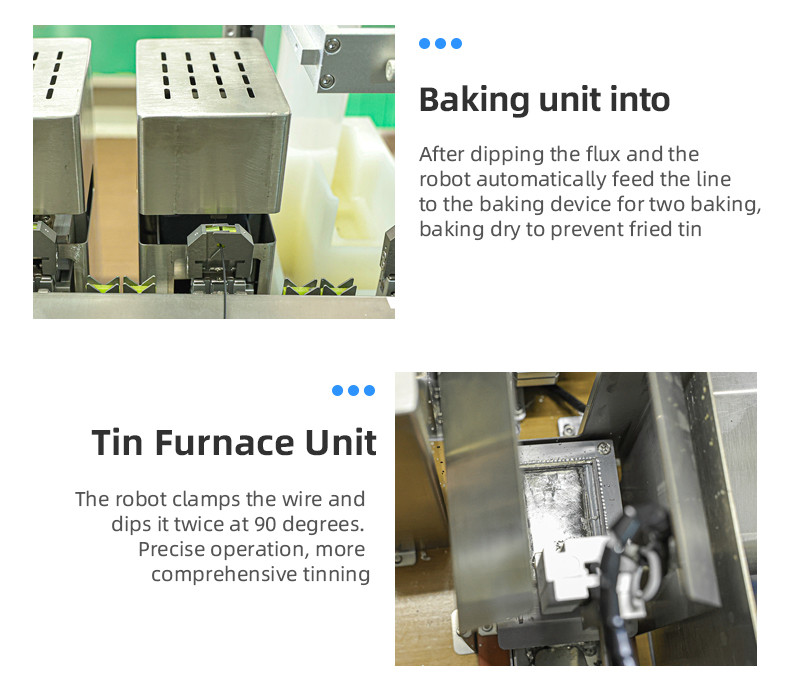

Tin Furnace Unit

The robot clamps the wire anddips it twice at 90 degreesPrecise operation,morecomprehensive tinning

Baking unit into

After dipping the flux and the

robot automatically feed the lineto the baking device for two baking,baking dry to prevent fried tinning

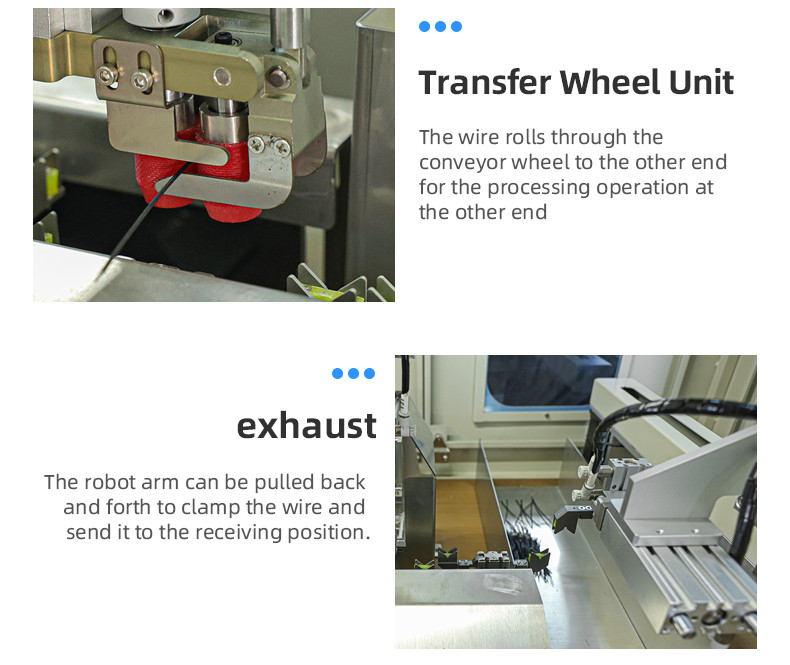

exhaust

The robot arm can be pulled backand forth to clamp the wire andsend it to the receiving position

Transfer wheel Unit

The wire rolls through the

conveyor wheel to the other endfor the processing operation atthe other end

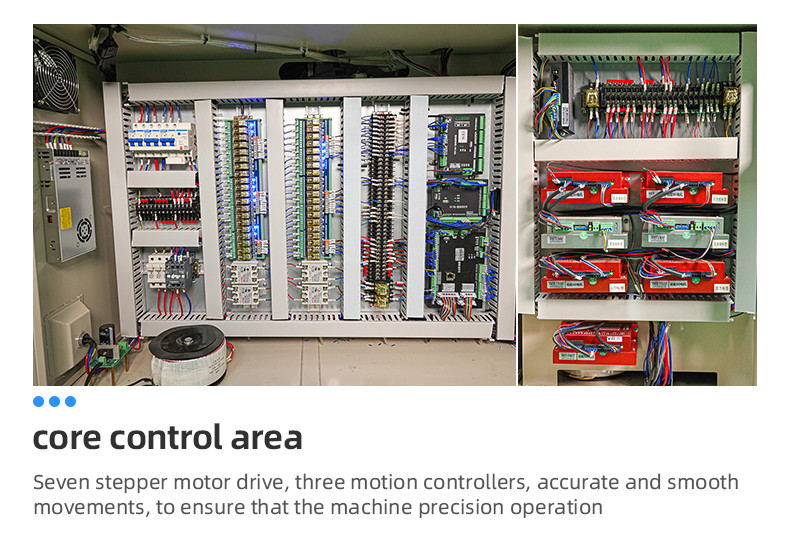

core control area

Seven stepper motor drive, three motion controllers, accurate and smoothmovements,to ensure that the machine precision operation