- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

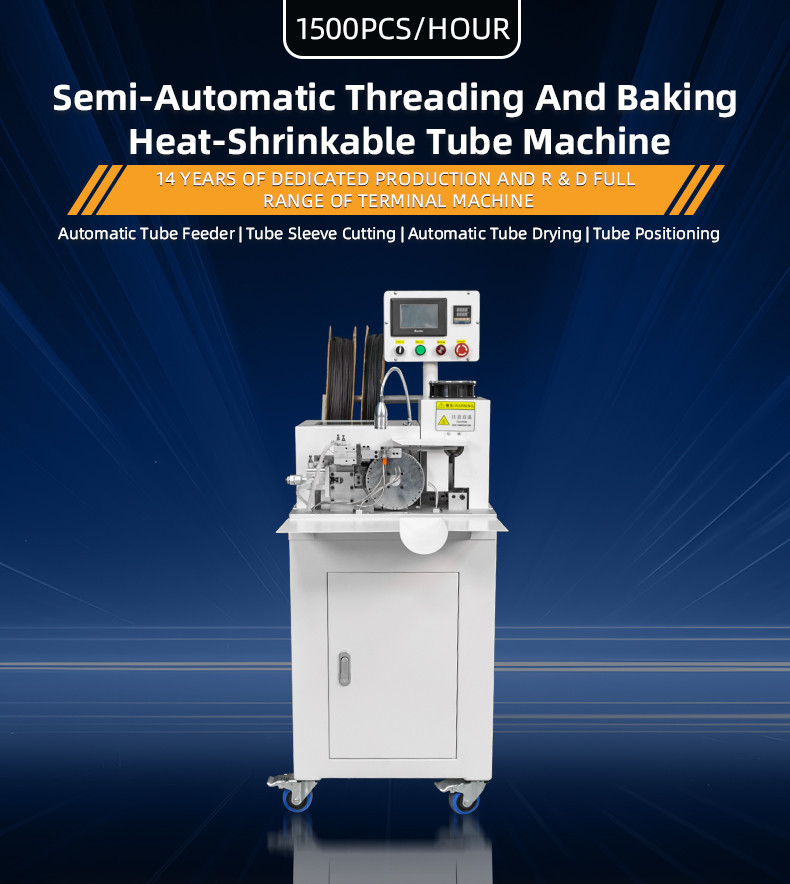

TR-RG13 Semi-Automatic Threading and Baking Heat Shrinkable Tube Machine

- group name

- Inserting Heat Shrink Tube Baking Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-RG13

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Sat, 28 Feb 2026 02:56:27 GMT

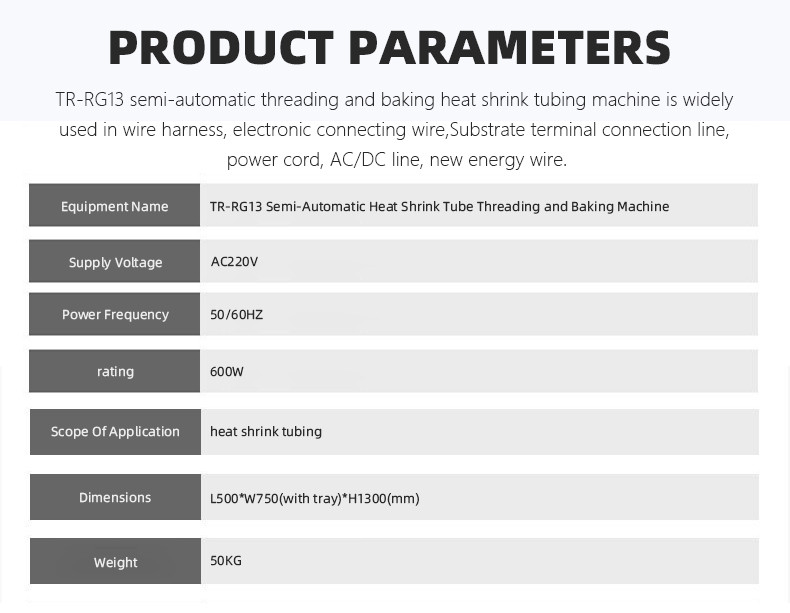

Paramtents

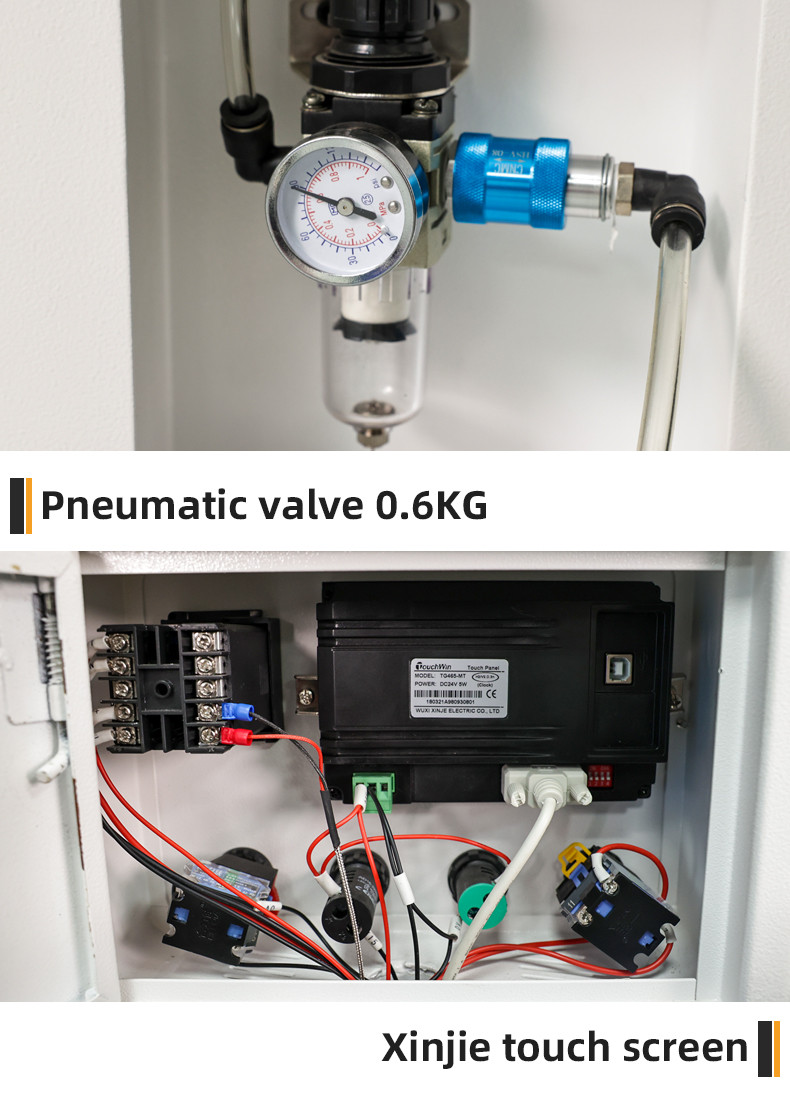

Power AC220V/50HZ,

Feature Stable Performance

Warranty 1year

Contact Lily 0086-13715588365

Function Threading and Baking Heat Shrinkable Tube Machine

Power 600W

Packging & Delivery

-

Min Order1 piece

Briefing

TR-RG13 Semi-Automatic Threading and Baking Heat Shrinkable Tube Machine

Detailed

TR-RG13 Semi-Automatic Threading and Baking Heat Shrinkable Tube Machine

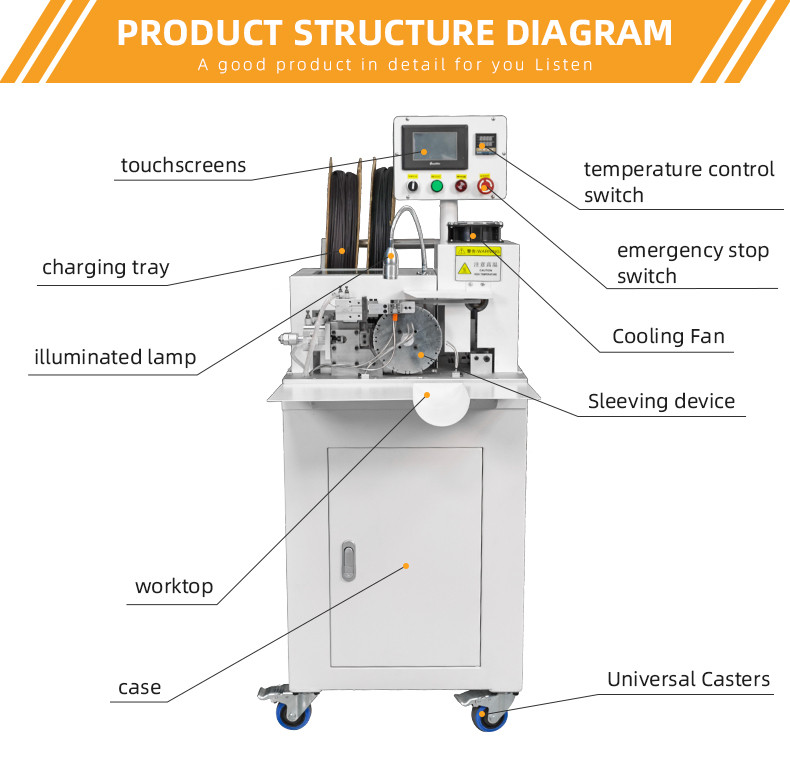

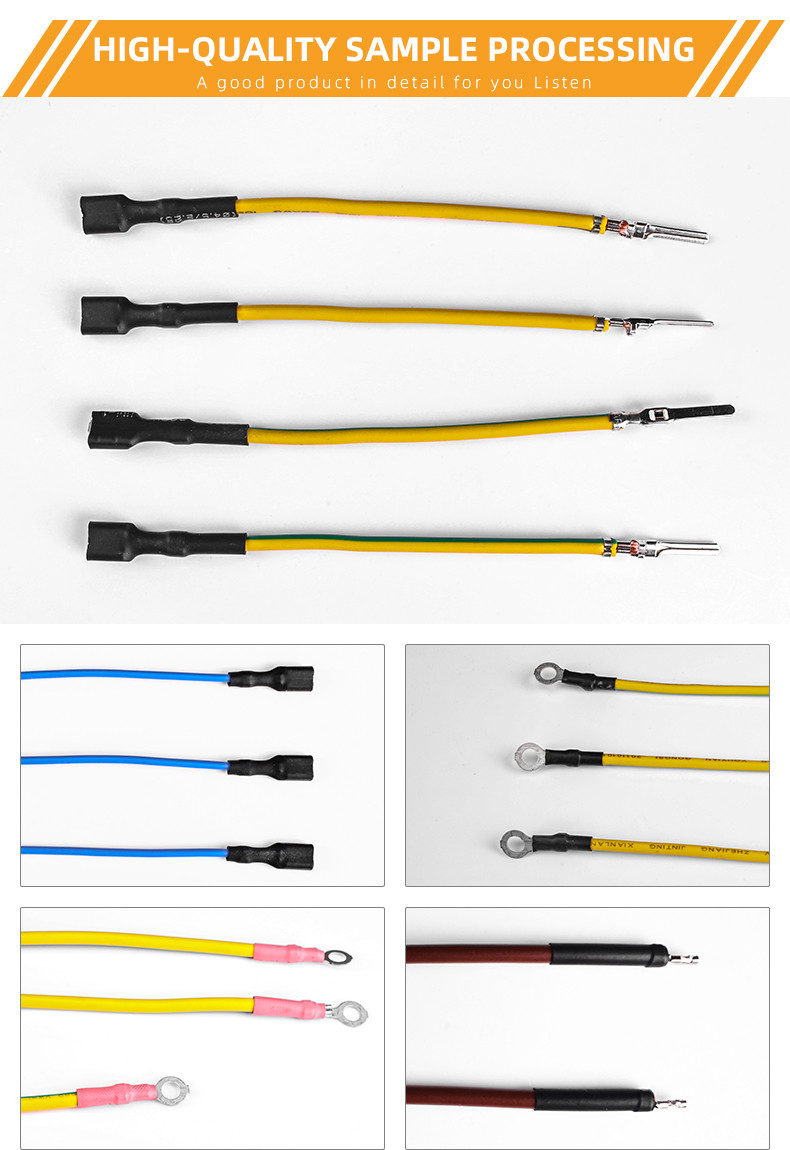

Function: Penetrating heat shrinkable pipeand baking heat shrinkable pipeProduct features: One out, three efficiency doublesMore applicable pipe diametersCustomized according to customer requirementsHigh adhesion and material saving

MACHINE WORKFLOW

01.Pipe Feeding

The casing of the length required for the job is fed by the feeding mechanism, and the pressure of thefollower wheel to the main wheel is adjiusted so that the casing is fed efficiently but without deforming thecasing.

02.cutting

The pipe cutting mechanism will cut off the casing sent out by the pipe feeding mechanism, the pipecutting blade is closed without gap, the cut is burr-free and the quality of pipe cutting is high.

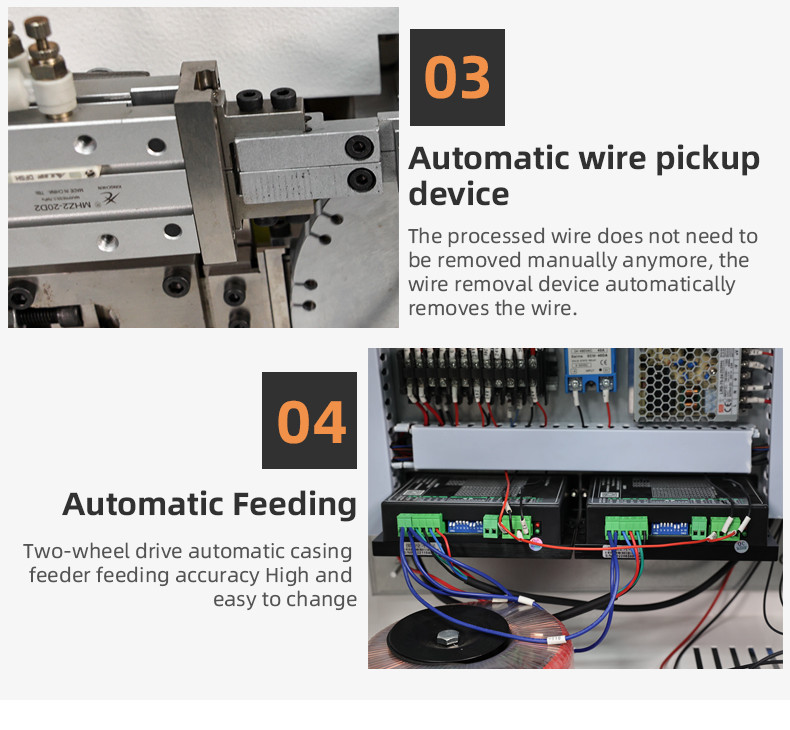

03.Threadinc

Manually thread the wire into the auide clamp mechanism, which inserts the product into the casing andlimits one end of the casing to ensure that the casing does not move, enabling accurate positioning;.

04.Baking

The air outlet tube can be adjusted up and down, left and right, forward and backward, so that the two airoutlet holes at the front end of the air outlet tube are aligned with the slots in the holes of the disk casing,so as to maximize the use of its thermal energy in the blowing out of hot air.

05.Finished Product

After the baking time is set, the heating tube automatically returns to its original position and the guidingclamp opens to take out the finished wire.