- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

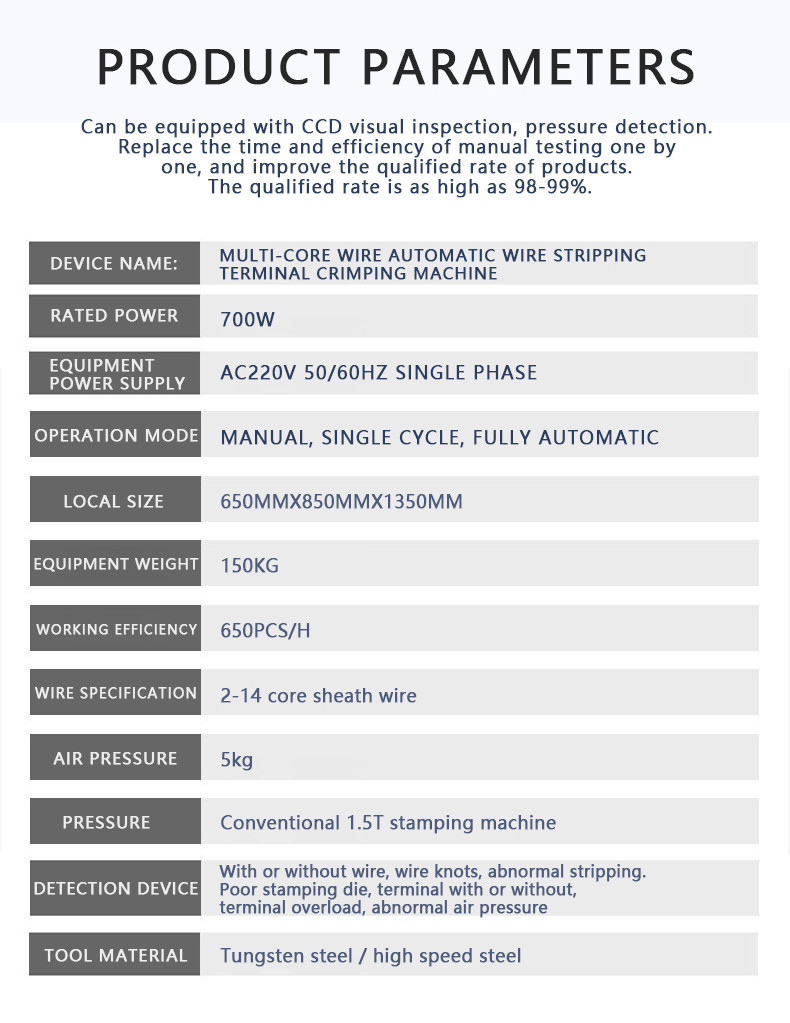

TR-HT03 Multi-core Wire Automatic Stripping And Terminal Crimping Machine

- group name

- Auto insert shell crimp

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-HT03

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Mon, 09 Feb 2026 04:06:43 GMT

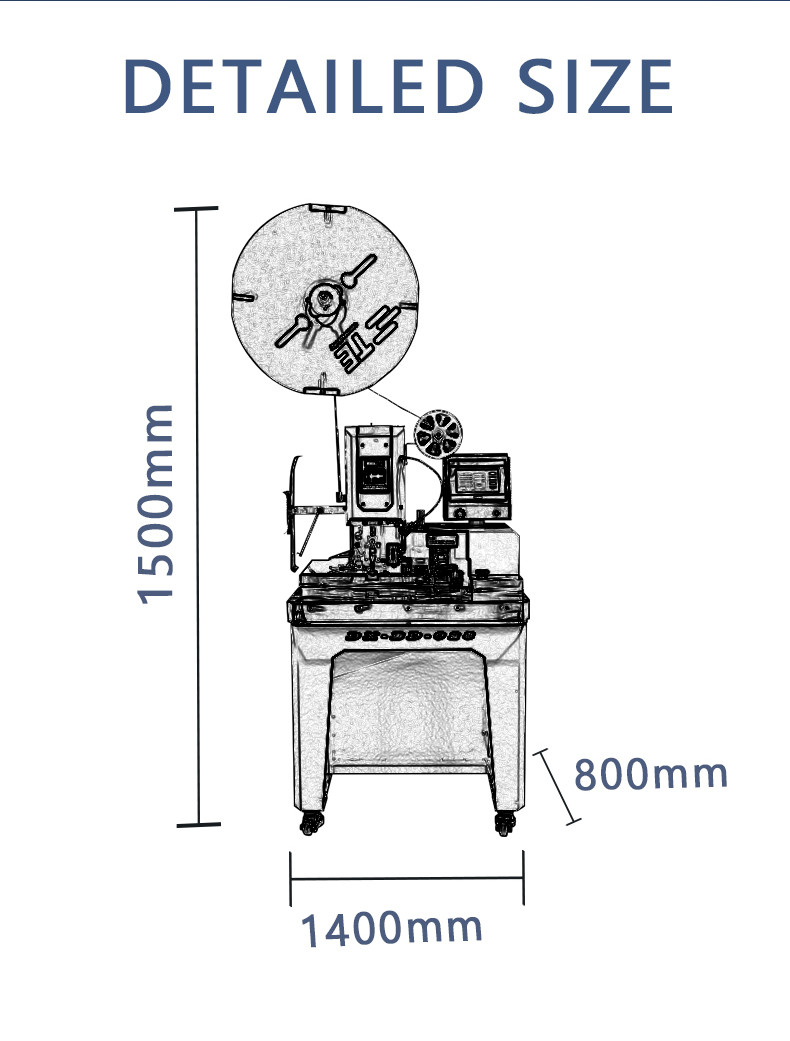

Paramtents

Power AC220V/50HZ,

Application Double end Terminal Machine

Feature Stable Performance

Warranty 1year

Control Servo and Step motor

Contact Lily 0086-13715588365

Packging & Delivery

-

Min Order1 piece

Briefing

Fully automatic high-speed double-head insert plastic shell tin dipping machine

Lily +8613715588365

Lily +8613715588365

Detailed

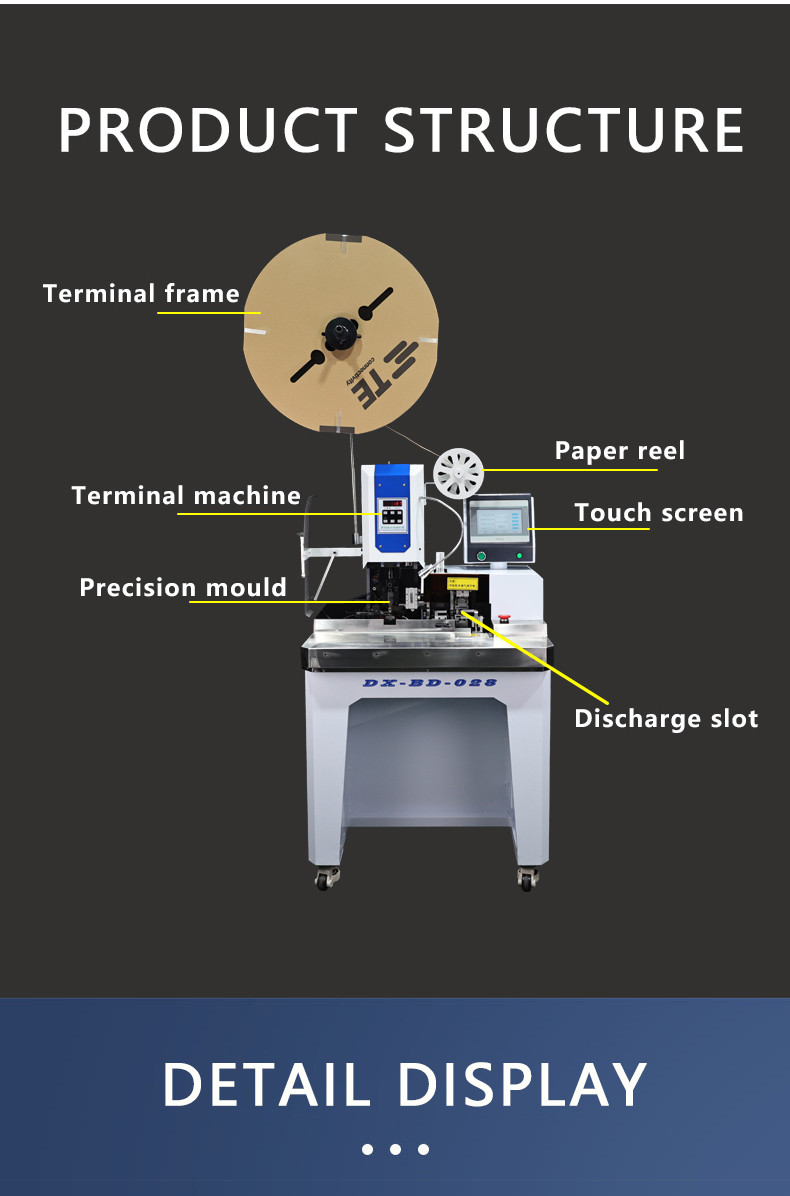

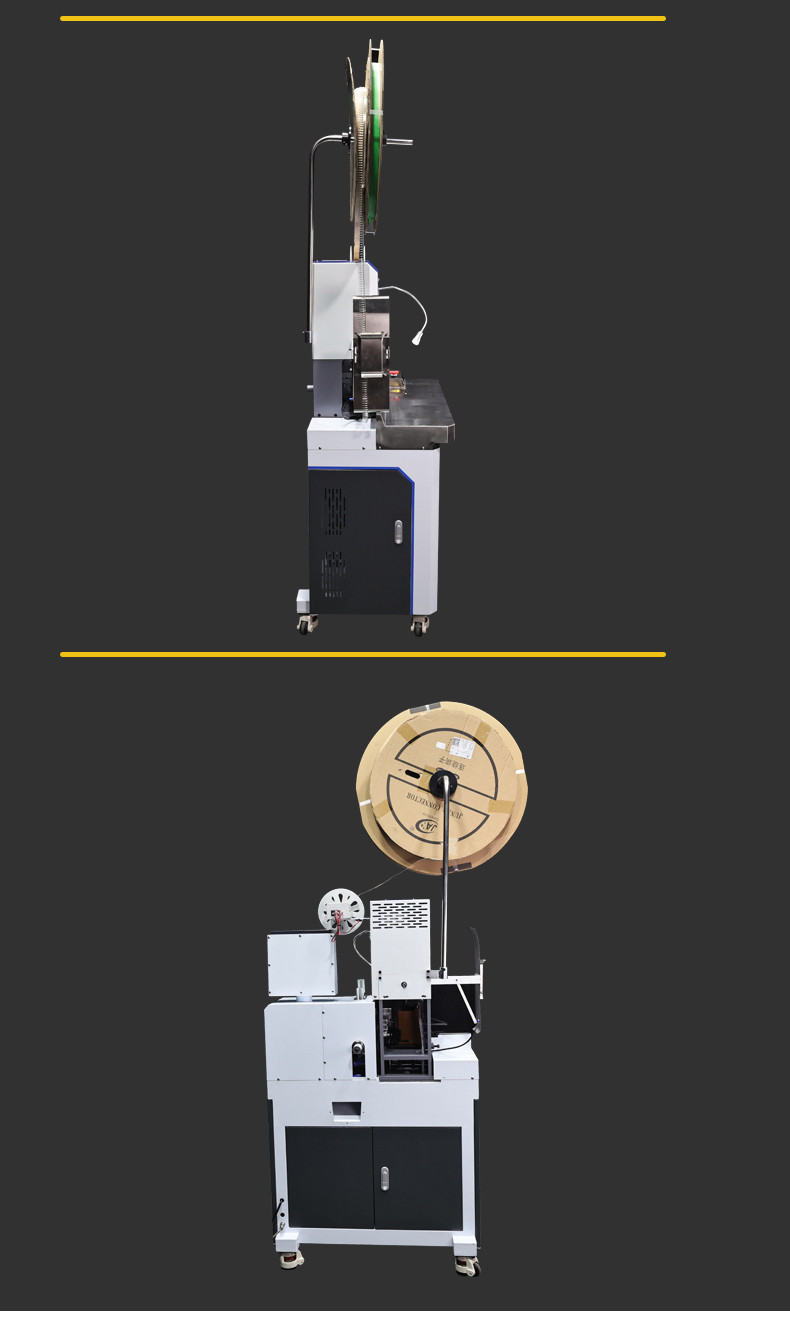

TR-HT03 Multi-core Wire Automatic Stripping And Terminal Crimping Machine

Equipment function: the front and rear ends are pierced through the shell, and the front end can be pierced through the shell and the rear end can be dipped in tin

Cost saving: the front and rear ends are pressed through the shell, and the rear end is dipped in tin. All processes are automatically completed, saving production costs for customers.

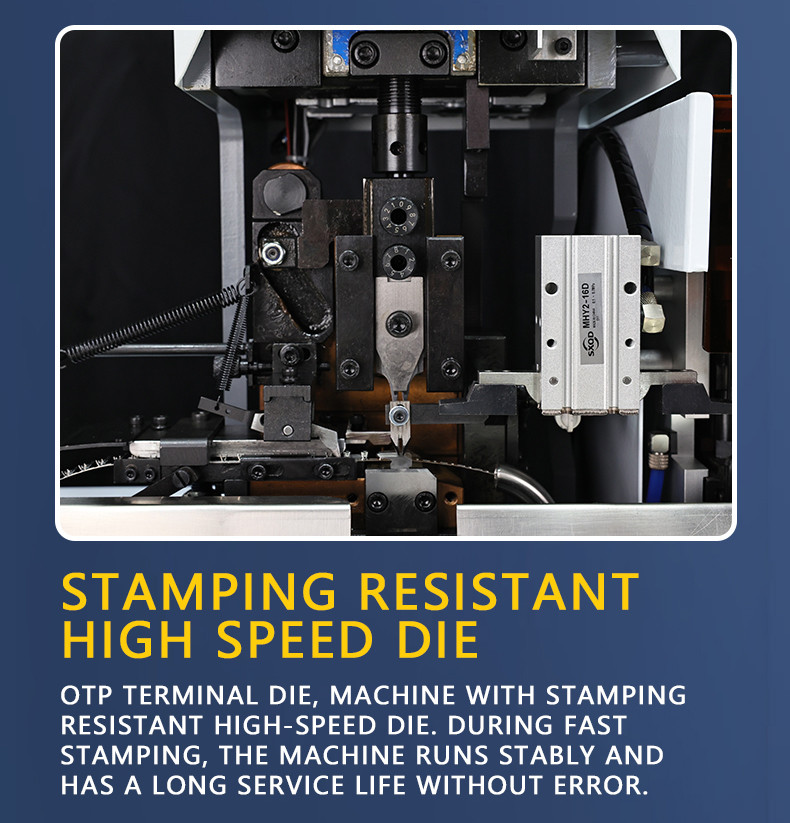

Good stability: The crimping end adopts eccentric shaft and cam structure, the crimping force of the terminal is balanced, the crimping of the terminal is neat, and the consistency is good.

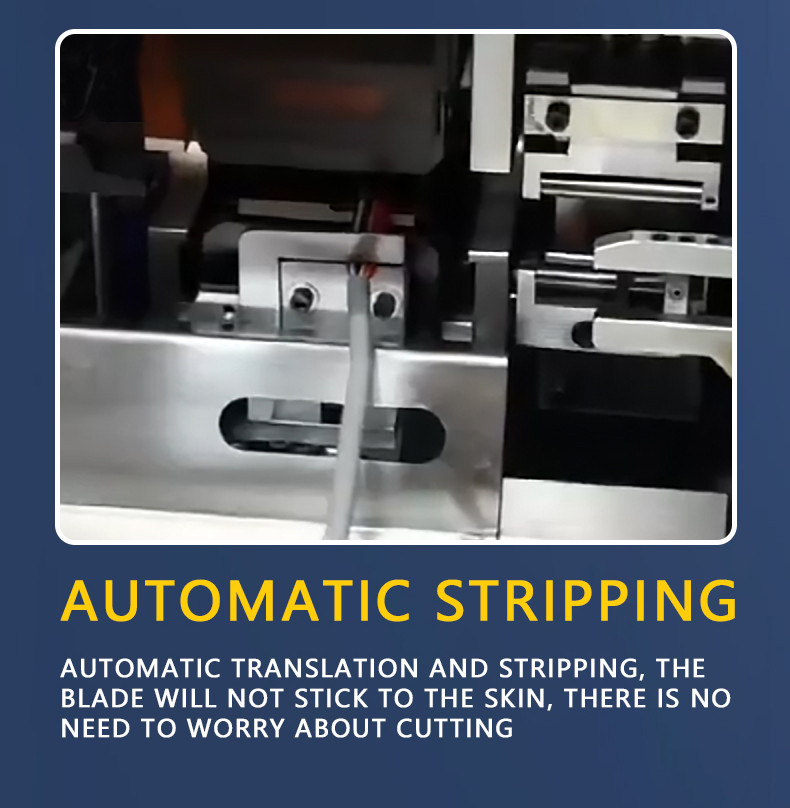

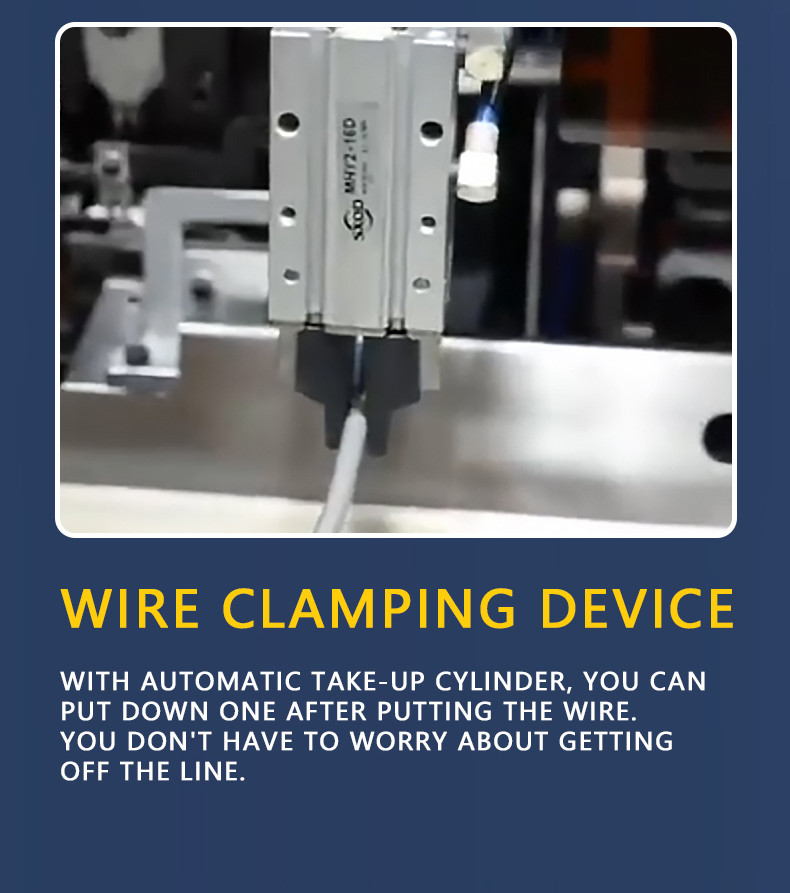

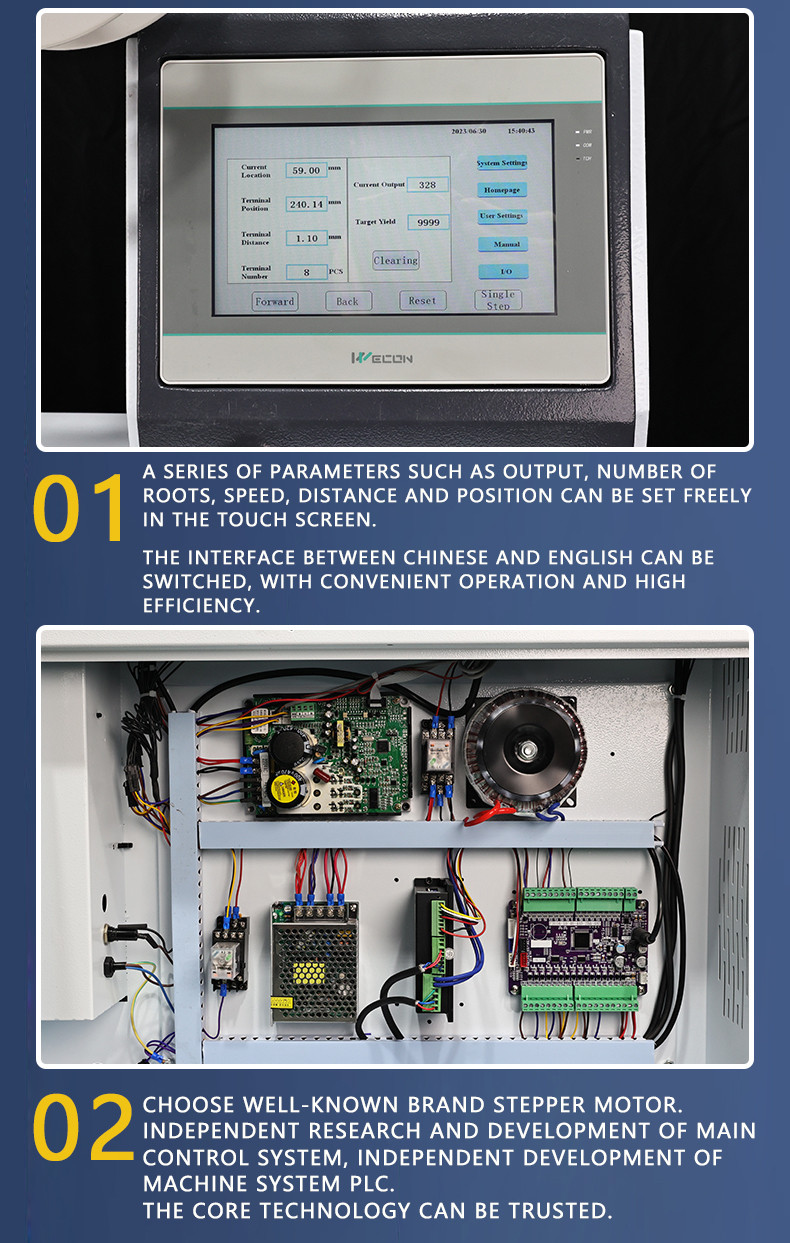

High precision: Servo motors are used to control cutting, peeling, pressure end positioning, shell feeding, shell piercing, and precise positioning.

Simple operation: touch screen operation, easy parameter setting and operation, easy to understand at a glance, ordinary employees only need simple training, and one person can operate several devices.

HIGH-END DOUBLE-ENDED RUBBER SHELL DIPPED TINTERMINAL CREATED BY JAPANESE INGENUITY

SAMSUNG, DJI AND OTHER WELL-KNOWN BRANDS DESIGNATEDGLOBAL WIRE HARNESS EQUIPMENT SUPPLIERS