- Home

- About us

- Products

- Terminal Crimping Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

- Faqs

- News

- Certificate

- Contact us

TR-1600 Upgraded Version of Automatic Wire Stripping and Terminal Crimping Machine

- group name

- Wire Stripping and Terminal Crimping Machine

- Min Order

- 1 piece

- brand name

- Turing

- model

- TR-1600

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash

- update time

- Mon, 02 Feb 2026 01:40:30 GMT

Paramtents

Power AC220V/50HZ,

Application Tin Dipping Machine

Feature Stable Performance

Warranty 1year

Control Servo and Step motor

Contact Lily 0086-13715588365

Packging & Delivery

-

Min Order1 piece

Briefing

TR-1600 Upgraded Version of Automatic Wire Stripping and Terminal Crimping Machine

Detailed

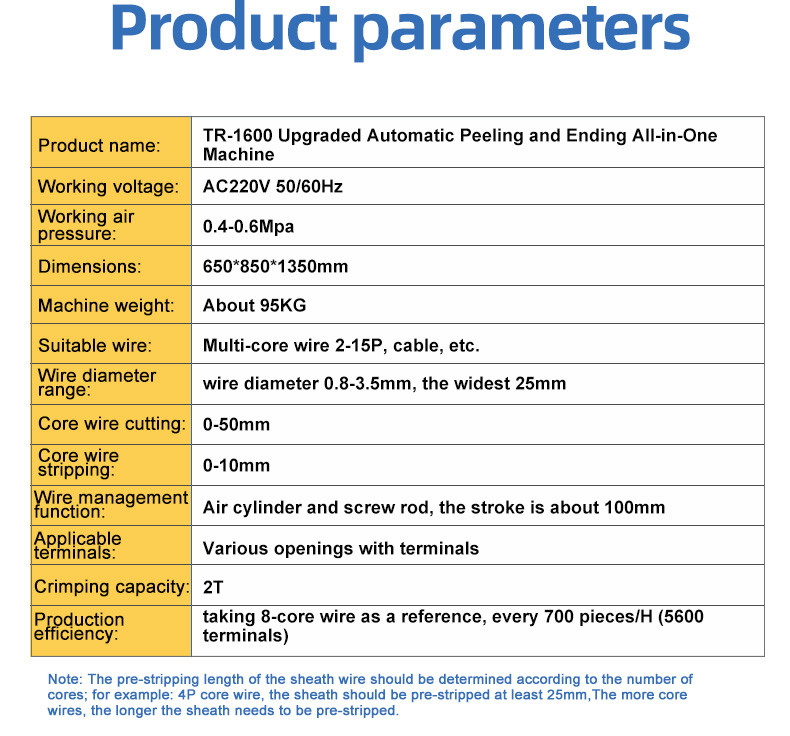

TR-1600 Upgraded Version of Automatic Wire Stripping and Terminal Crimping Machine

Working voltage:AC220V 50/60Hz

Working air pressure:0.4-0.6Mpa

Dimensions:650*850*1350mm

Machine weight:About 95KG

Suitable wire:Multi-core wire 2-15P,cable, etc.

Wire diameter range:wire diameter 0.8-3.5mm, the widest 25mm

Core wire cutting:0-50mm

Core wire stripping:0-10mm

Wire management function:Air cylinder and screw rod, the stroke is about 100mm

Applicable terminals:Various openings with terminals

Crimping capacity:2T

Production Efficiency:taking 8-core wire as a reference, every 700 pieces/H (5600terminals)

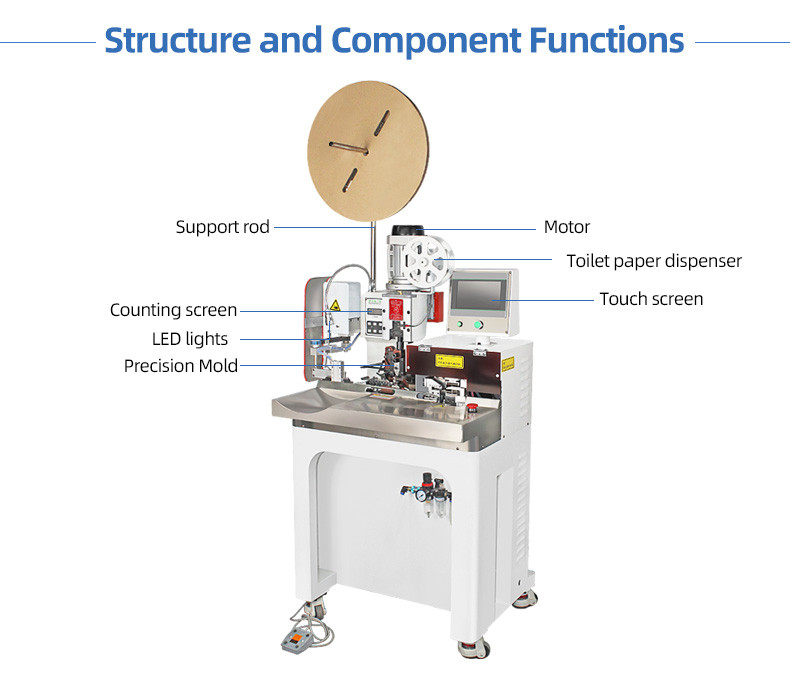

All-in-one machine for automatic cable management,stripping, and end cutting

Note: The pre-stripping length of the sheath wire should be determined according to the number ofcores; for example: 4P core wire, the sheath should be pre-stripped at least 25mm,The more corewires, the longer the sheath needs to be pre-stripped.

Note: The pre-stripping length of the sheath wire should be determined according to the number ofcores; for example: 4P core wire, the sheath should be pre-stripped at least 25mm,The more corewires, the longer the sheath needs to be pre-stripped.